Diagnostics Window

The Model Diagnostics window is a feature introduced in AFT Arrow 8. It is intended to help users check on a number of settings that may have been changed during the model-building process and that may affect the model results.

The Model Diagnostics window can be accessed from the Tools menu.

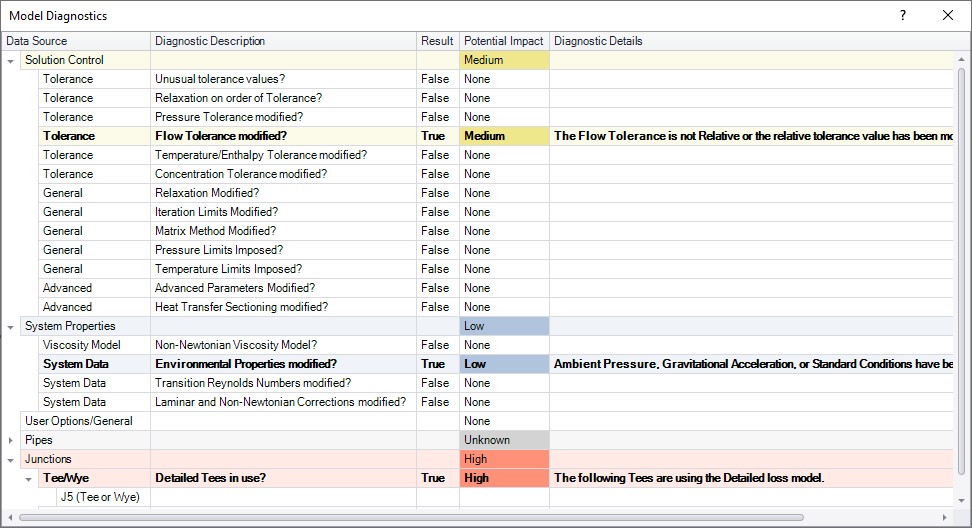

When the Model Diagnostics window is opened most input will be checked, and the results will be displayed in a tabular format. Items of note will be highlighted based on the impact each identified item may have on the results. It should be noted that not all items identified by this window will have a negative impact on results. Rather, the identified items are settings that have frequently been incorrectly applied by other users. This is not an exhaustive list of troubleshooting items, though most common issues are included.

Data in the Model Diagnostics Window is organized by the Data Source, which is the window where that setting/input is defined. Any item that may negatively impact the model will be highlighted based on its potential to affect the model, as shown in the Potential Impact column. For pipe and junction diagnostic items, the pipe(s)/junction(s) that were identified will be listed below the diagnostic item. For an example, see Figure 1 below. The Diagnostic window indicates that the Flow Tolerances and the Environmental Properties for the model have been modified from the default, which is unusual. Model Diagnostics also indicates the junction J5 is using the detailed tee loss model, which can prevent convergence in some cases if not defined properly.

Figure 1: Example of the Model Diagnostics window

Related Topics

Transfer Results to Initial Guesses

Poor Compressor/Fan Curve Fits

Troubleshooting Resistance Curves

Use the Output Window Sort Feature

Lower the Flow Rate Relaxation

Make Initial Flow Rate Guesses for Pipes

Break a Large Model Into Submodels

Try a Different Fluid, Equation of State or Accuracy Option

Using Lumped Adiabatic as a Starting Point