NFPA Firewater System (Metric Units)

NFPA Firewater System (English Units)

Summary

This problem walks through building a hydraulic model of a fire water sprinkler system using Fathom's NFPA features. This example is based off of figure B.2 (a) and associated calculations from NFPA 15 standard 8.5.3.1.

In this example, a firewater spray nozzle system is hydraulically modeled. The system consists of 28 spray nozzles and is supplied by a fixed pressure source. As the design engineer, it is your responsibility to ensure that all spray nozzles receive at least

Topics Covered

-

Modeling a fire water spray system

-

Making groups

-

Using NFPA features

-

Generating an NFPA report

-

Using Excel Change Data

Required Knowledge

This example assumes the user has already worked through the Beginner - Three Reservoir example, or has a level of knowledge consistent with that topic. You can also watch the Fathom Quick Start Video Tutorial Series, as it covers the majority of the topics discussed in the Three-Reservoir Problem example.

Model Files

This example uses the following files, which are installed in the Examples folder as part of the AFT Fathom installation:

Step 1. Start AFT Fathom

From the Start Menu choose the AFT Fathom 13 folder and select AFT Fathom 13.

To ensure that your results are the same as those presented in this documentation, this example should be run using all default AFT Fathom settings, unless you are specifically instructed to do otherwise.

Step 2. Open the Model

Open the Metric - NFPA Firewater System - Initial.fth model file listed above, which is located in the Examples folder in the AFT Fathom application folder. Save the file to a different folder.

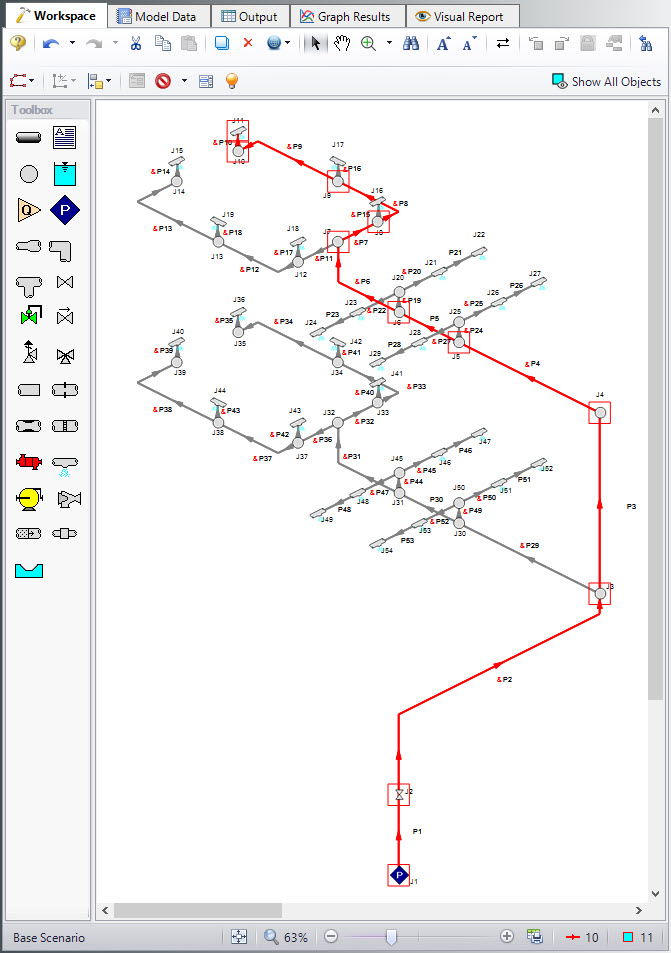

The model should appear as shown in Figure 1.

Figure 1: Initial model for NFPA Firewater System example

Step 3. Define the Fluid Properties Group

-

Open Analysis Setup from the toolbar or from the Analysis menu.

-

Open the Fluid panel then define the fluid:

-

Fluid Library = AFT Standard

-

Fluid = Water (liquid)

-

After selecting, click Add to Model

-

-

Temperature = 21 deg. C

-

Step 4. Define the Miscellaneous group

While still in the analysis setup, expand the Miscellaneous drop down and open the NFPA panel. Check the box next to Enable NFPA. This will enable various features throughout the software such as NFPA internal fittings & losses for pipes, equivalent length loss model for junctions, NFPA report, etc. Keep the Initial Values the same. A group for the NFPA report will be selected later.

Step 5. Define the Pipe and Junction Properties

At this point, the first two groups are completed in Analysis Setup. The next undefined group is the Pipes and Junctions group. To define this group, the model needs to be assembled with all pipes and junctions fully defined. Click the "Ok" button to save changes to the analysis setup and return to the workspace. At this point a user would need to draw their own network using the tools in the toolbox, but to save some time the piping layout for this model has already been created.

With the system in place, we now need to enter the properties of the objects. Because this model is large, all input has been added to a specially-configured Excel Change data spreadsheet that is included in the Examples folder and will be used to change the input to match the values in this example. Before importing this spreadsheet, it is necessary to define values in each pipe and junction because the Excel Change data spreadsheet is only capable of changing input data, not entering new data.

To quickly enter input data before using the Excel Change data spreadsheet, we will use the Global Pipe and Junction Editing features. If you are going to use Excel Change data to change the input you already have in your model, the values that you initially input in the model act simply as place holders and the value itself is not important. It is crucial, though, that you ensure that the units for each value that will be changed are specified correctly, because the Excel Change data spreadsheet will not change these units (it will only change the value itself).

Pipe Properties

To globally edit the pipes, select Global Pipe Edit from the Edit menu. Click All to select all pipes. Next, click Select Pipe Data and enter the following inputs in the pipe properties window.

-

Pipe Material = Steel - ANSI

-

Pipe Geometry = Cylindrical Pipe

-

Size = 1 inch

-

Type = STD (schedule 40)

-

Friction Model = User Specified

-

Data Set = Hazen-Williams Factor

-

Value = 120

-

Length = 3 meters

In the Parameters to Change section, click All to apply all changes to the selected pipes, then click Apply Selections at the bottom. Then click OK.

Next, fittings a losses will need to be added to various pipes throughout the system. On the fittings & losses tab of the pipe properties window move the slider from "Use K Factor" to "Use Equivalent Lengths" then specify the Fittings for each pipe according to the table below.

Note: Pipes that have Fittings & Losses entered in them will now have a red & displayed next to them. The symbol and display settings can be customized in User Options.

Table 1: Fittings and Losses for pipe input in NFPA model

| Pipes | Fitting Type | Quantity |

|---|---|---|

| 4, 6, 8, 10, 12, 14, 31, 33, 35, 37, 39 | Elbow, 90 deg. standard | 1 |

| 2, 9, 13, 34, 38 | Elbow, 90 deg. standard | 2 |

| 7, 11, 19, 20, 22, 24, 25, 27, 29, 32, 36, 40, 41, 42, 43, 44, 45, 47, 49, 50, 52 | Tee or Cross, (flow turned 90 deg.) | 1 |

| 15, 16, 17, 18, 40, 41, 42, 43 | Elbow, 90 deg. standard and Tee or Cross, (flow turned 90 deg.) | 1 Tee and 1 Elbow |

Junction Properties

To globally edit the junctions, select Global Junction Edit from the Edit menu. Next, click the appropriate junction based on what you are inputting. For example, Spray Discharge. Click All to select all junctions in the list. Then, click Select Spray Discharge Data and enter the following inputs in the pipe properties window. Repeat this process for all junction types in the model using the inputs below.

-

All Spray Discharges

-

Elevation = 3 meters

-

Loss Model = K (Fire Sprinkler)

-

Exit Properties = Pressure

-

Exit Pressure = 0 barG

-

K (Fire Sprinkler) = 3 liters/min per square root of bar

-

Number of Sprinklers = 1

-

-

All Branches

-

Elevation = 3 meters

-

-

J1 Assigned Pressure

-

Elevation = 0.15 meters

-

Pressure = 4.41 barG

-

Pressure Specification = Static

-

-

J2 Valve

-

Inlet Elevation = 0.76 meters

-

Outlet Elevation = 1.22 meters

-

Valve Data Source = Equivalent Length (Metric)

-

Equivalent Length = User Defined

-

Equivalent Length (User) = 3.96 meters

-

Import Excel Change Data

After you have input for all pipes and junctions, import the Excel Change data spreadsheet. To do this, import the spreadsheet in the Examples Help file entitled Metric - NFPA AFT Transfer Spreadsheet.xlsx by clicking on File > Import Excel Change Data, and then browsing to this spreadsheet. After all changes were made, a window will appear that lets you know that all changes were made.

Step 6. Create the NFPA Group

In order to generate an NFPA report, AFT Fathom needs to know the path for which you wish to generate the report. Generally, this report is developed for the hydraulically most remote path. For this model the hydraulically most remote path is either the path to J11 or J15. For Fathom to generate a path it will first need a group containing all pipes and junctions along the desired flow path.

To create a group, select all pipes and junctions that are along the flow path. For this example you will need to select pipes P1, P2, P3, P4, P5, P6, P7, P8, P9, and P10, and junctions J1, J2, J3, J4, J5, J6, J7, J8, J9, J10, and J11 (see this path selected in Figure 2). Note, to select multiple objects, hold the shift key while selecting each with this mouse. Alternatively, you can select these pipes and junctions directly from the Group Manager. Once these pipes and junctions are selected, open the Group Manager by going to Edit > Groups > Manager. Click on Create Group and name the group NFPA Path. Make sure this path is selected under Existing Groups, then under both the Pipes in Group and Junctions in Group columns, select Workspace. Press OK to confirm this group.

The group we just selected contains the hydraulically most remote path, but this information was simply provided for the sake of convenience in this example and is not frequently known without modeling the system. If you have the GSC module, you can use it to determine the most hydraulically remote path. See the Example problem NFPA Firewater System - GSC if you are interested in seeing how to use the GSC module for this. Otherwise, if the hydraulically most remote path is not known, you will need to dig through Fathoms output to determine which spray nozzle is receiving the least flow.

Step 7. Specify the NFPA Path

Once you know the hydraulically most remote path, you will generate an NFPA report for this path. To specify which path in AFT Fathom you want to generate the NFPA report for, open Analysis Setup and go to the NFPA panel. Select the group in the Select a Group for the NFPA Report list.

Step 8. Run the Model

Click Run Model on the toolbar or from the Analysis menu. This will open the Solution Progress window. This window allows you to watch as the AFT Fathom solver converges on the answer. Now view the results by clicking the Output button at the bottom of the Solution Progress window.

You will notice there are numerous cautions about the pipe lengths being shorter than the elevation change. This model used pipe lengths and elevations based off a NFPA example. In the NFPA example, the length of the spray discharges raised the outlet height of the junction. Fathom treats junctions as single points in space, so to keep the inputs identical the pipe length had to be a little bit short.

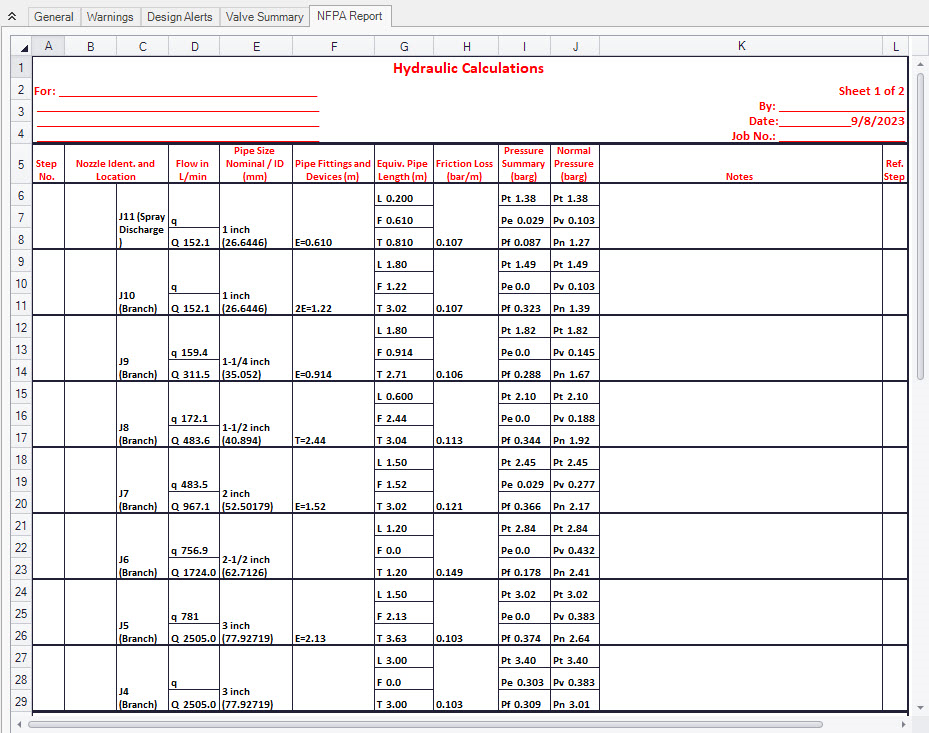

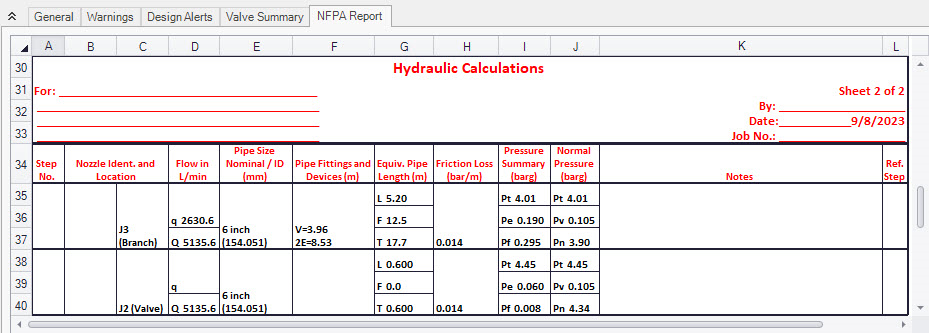

Step 9. Examine the Output

The Output window contains the NFPA Report, as well as the standard AFT Fathom output parameters. To view the NFPA Report, click on the NFPA Report tab in the General section of the Output window. You can expand this section by dragging the border down. The NFPA Report can be printed from File > Print NFPA Report, or you can select all cells by clicking the top-left corner and copy-paste into Excel for modifications. The NFPA Report for this model is shown in Figure 3a and Figure 3b.

Conclusion

AFT Fathom allows you to display the hydraulic calculations for an NFPA report. In this example, you have built a model of a firewater system and generated an NFPA hydraulic report. In this report we can see that the minimum pressure for this system is

To those familiar with the NFPA Example this was based off, you may notice a slight difference in the minimum pressures calculated by Fathom. This is because Fathom uses a more detailed model to account for various behavior in the system. You can read more about these differences on the NFPA Panel topic.