Optional Input for Pipes

The Initial Flow Guess for a pipe can be specified. An appropriate initial guess can decrease the number of iterations required to arrive at a converged solution.

The Solver generates initial guesses on its own, which is usually sufficient to get the Solver going in the right direction so a converged solution results. If this is not the case, user defined guesses can help obtain a solution.

A single pipe object can be specified as a number of parallel pipes. When multiple pipes are defined, the parameters in the pipe properties window represent only one of the parallel pipes.

The Special Condition for the pipe can be set to None or Closed. Setting this to closed prevents flow through the pipe, like closing a valve. A symbol (default of "X") will be placed before the pipe label and the pipe will appear dashed, indicating that it is closed.

A design factor can be used to add safety margins into the hydraulic analysis. For pipes, three design factors exist:

-

Pipe Friction - friction factor is multiplied by the design factor assigned to the pipe.

-

Pipe Fittings & Losses - total loss factor (K factor or Equivalent Lengths) is multiplied by the design factor assigned to the pipe.

-

Pipe Heat Transfer - the thermal resistance for each heat transfer layer is divided by the design factor assigned to the pipe.

The inlet and exit elevations of a pipe are equal to the elevations of the upstream and downstream junctions. The pipe elevation is assumed to vary linearly between the junctions. In other words, the pipe is assumed to be perfectly straight.

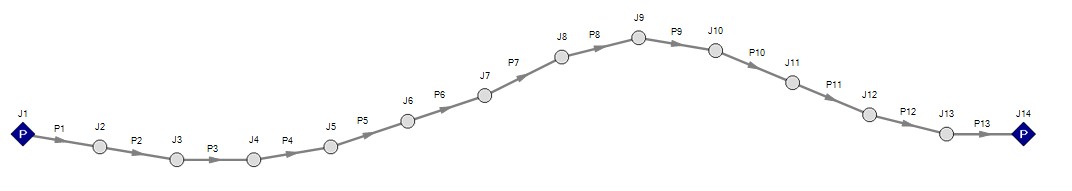

Modeling a large number of elevation changes with straight pipes would require a large number of junctions, as shown below:

Figure 1: Accounting for elevation changes with many pipes and junctions

This is tedious and not required for overall hydraulic calculations - only the elevation change across a (fluid full) pipe is needed. However, intermediate pressure results along the pipe will be affected.

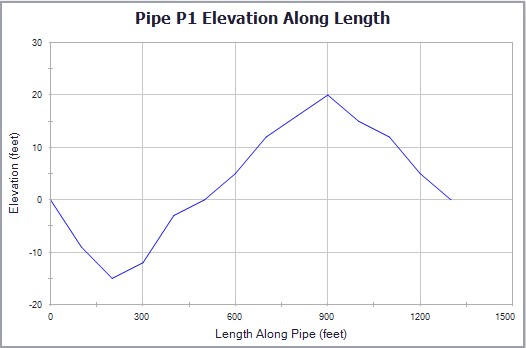

For example, Figure 1 shows elevation extremes both lower and higher than the elevations at the ends of the pipeline. Low points may exceed maximum allowable pressures, and high points could drop below vapor pressure. If this is modeled as a single straight pipe these issues would not be easily identified. In fact, if these pipes were replaced with a single pipe it would show no elevation change at all!

Instead of using a large number of pipes, these effects can be accounted for in a single pipe using intermediate pipe elevation feature.

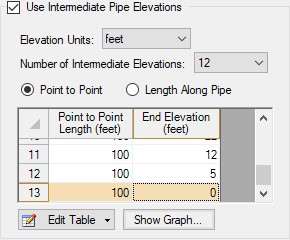

With length defined, check Use Intermediate Pipe Elevations, choose the elevation units, the number of intermediate elevations (a 2 segment pipe has 1 intermediate elevation), and whether the entered values are Point to Point or Length Along Pipe.

Figure 2: Intermediate Elevations - Identical Profiles defined with both methods

AFT Fathom will ensure the total length matches the length on the Pipe Model tab. It does so by fixing the length of the final section to the difference between the sum of the lengths in the table and the actual length entered by the user. The end elevation is also fixed by the downstream junction. If the user later modifies the downstream junction elevation, the pipe's final elevation section will be automatically updated.

After the intermediate elevations have been entered, a graph showing the data can be displayed. Below is the profile graph of the pipe described above.

Note that a pipe with intermediate elevations entered can be split into multiple pipes connected with branches at the intermediate elevation points. See Joining and Splitting Pipes for more information.

Figure 3: Intermediate Elevation Graph