Pump Efficiency Data

Best Efficiency Point (BEP)

By defining an efficiency or power curve, the Best Efficiency Point of the pump can be found. Optionally, the calculated value can be overridden with a user-defined value in the Pump Configuration window. It is generally desirable to operate pumps as close to the BEP as possible. The Pump Summary tab in the Output can display the BEP, and the % of BEP which indicates how close the operating point is to the BEP.

Power and Efficiency Calculations

Various stages of power or efficiency data relating to a pump assembly can be added to a pump junction.

The most basic value that can be accounted for is the pump efficiency or power curve. This curve, entered in the Pump Configuration window, is used to determine the power/efficiency being delivered to the pump itself - the Shaft Power.

The Solver will determine the total dynamic head (ΔH) and flow (Q) through the pump via iteration for the unique system. Then, the Ideal Power (also called hydrodynamic power) can be directly calculated using the equation below:

where ρ is the fluid density at the pump and g is the gravitational acceleration. When a pump efficiency or power curve is entered on the Pump Configuration window, the power supplied to the pump, or Shaft Power, can be calculated:

where the pump efficiency comes from the pump curve at the given flow. On a pump's optional tab, further efficiency information can be defined:

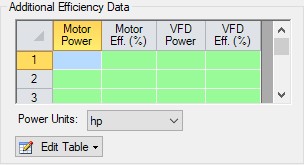

Figure 1: Additional Efficiency Data

Entries in this table must come in pairs - both Power and Efficiency values must be present. For example, if Motor Power is entered, the Motor Efficiency column must also be entered. You can enter only motor data, only VFD data, or both.

Motor Power in this instance refers to the output power of the motor, which is equal to the Shaft Power calculated previously. This is because the motor driver is mechanically coupled to the shaft and impeller. Because the Shaft Power is already known, it can be looked up inside this table using linear interpolation, and the corresponding Motor Efficiency is used to calculated the Motor Input Power:

VFD Power is used in a similar fashion. The VFD Power in Figure 1 refers to the output power of the VFD, which is identical to the Motor Input Power (but instead of being mechanically coupled, this is represented by an electrical connection). Because Motor Input Power was calculated, VFD Efficiency can be found from the table using linear interpolation, and VFD Input Power can be calculated:

VFD Input Power is equivalent to the Overall Power, viewable in the Pump Summary along with the other above values. Whenever an efficiency value is left undefined, it is assumed to be 1 (perfectly efficient).

Related Topics

Centrifugal (Rotodynamic) Pump

Junction X %BEP (Y%) is above/below the POR range

Related Examples