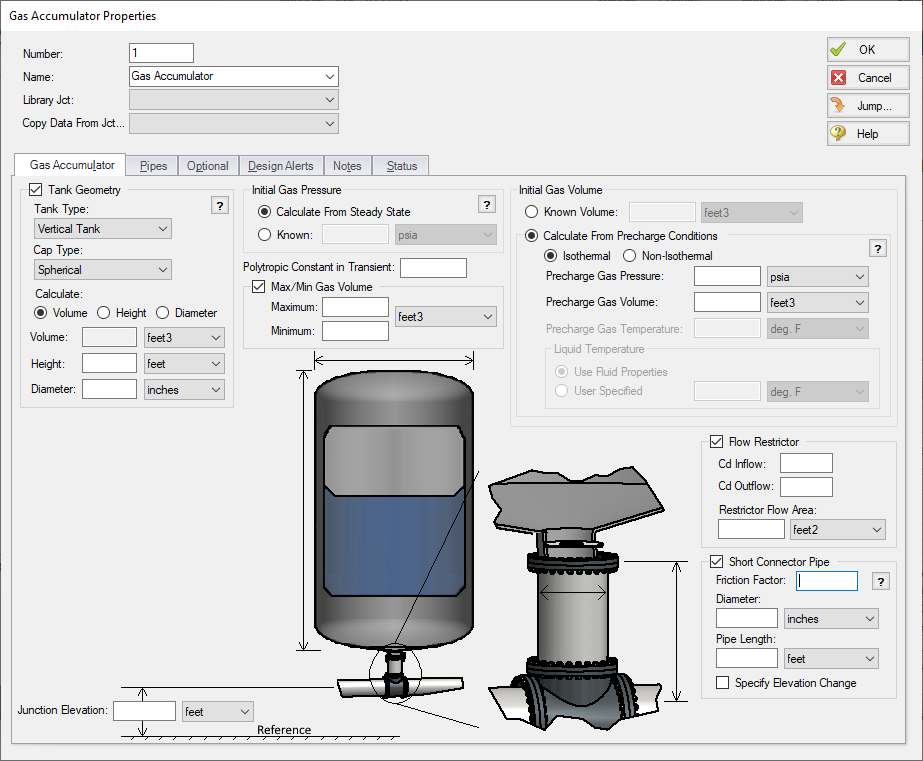

Gas Accumulator

The Gas Accumulator junction allows up to twenty-five connecting pipes. This junction type is useful for modeling a gas volume designed as a surge protection device (Figure 1). The Gas Accumulator may be integral with the pipe system, separated by an orifice, or by a short connector pipe. During steady flow the gas accumulator typically acts a loss-less branch junction, although it can be made to act like a pressure junction. This is discussed later in the gas accumulator section.

The Gas Accumulator Properties window follows the second of the two basic Properties window formats. A table displays the connecting pipe information. The table grows in size to accommodate up to twenty-five connecting pipes.

Figure 1: Schematic of a gas accumulator

Tank Geometry

The tank geometry is an optional input which allows Impulse to account for variations in the liquid level within the gas accumulator.

Th vertical and horizontal tank types are programmed to allow Impulse to calculate the tank volume, height, or diameter based on two provided dimensions. For non-cylindrical tanks the other geometry option can be selected, which requires the user to directly input Accumulated Volume vs Liquid Height data.

Cap type selections are available to define the geometry of the tank cap/head as are defined in Crookston 2011Crookston D. and Crookston R., "Calculate Liquid Volumes in Tanks With Dished Heads," Chemical Engineering, p. 66-63, September 2011. [Online]. Available: https://www.chemengonline.com/calculate-liquid-volumes-in-tanks-with-dished-heads/. [Accessed December 2021]. (see References for link).

Initial Gas Pressure

The Gas Accumulator provides two options for determining the steady state pressure at the accumulator.

-

Calculate From Steady State - This option treats the gas accumulator junction like a lossless branch junction during the steady state. The pressure at the inlet of the gas accumulator is determined based on the steady state pressure in the connected pipes.

-

Known - This option fixes the gas pressure to the specified value. The gas accumulator junction then acts like an assigned pressure junction based on the defined gas pressure. If the tank geometry is defined the hydrostatic pressure from the liquid is also accounted for. The main purpose of this option is to model a pressurizer as is discussed further below in the Known Pressure for Steady Flow section.

Initial Gas Volume

The Gas Accumulator provides two options for determining the steady state gas volume in the accumulator.

-

Known Volume - This option will fix the gas volume during the steady state to the specified value.

-

Calculate From Precharge Conditions - This option will determine the steady state gas volume using the provided precharge conditions. The thermodynamic calculations for the steady state can be treated as isothermal or nonisothermal as described below:

-

Isothermal - Impulse assumes that the temperature is constant, so PV = constant. The steady state volume can be determined directly using the precharge volume and pressure, and the steady state pressure.

-

Non-Isothermal - Impulse assumes that the gas is an ideal gas in the steady state, so PV/T = constant. The precharge temperature must be provided in addition to the pressure and volume. The steady state volume can then be calculated using the precharge conditions, the steady state pressure, and the steady state temperature. The steady state gas temperature is assumed to be equal to the liquid temperature in the gas accumulator. The User specified liquid temperature option may be required if the fluid specified in the Fluid panel did not have a specified temperature.

-

Polytropic Constant in Transient

Regardless of the method used to calculate initial conditions the gas volume will change during the transient according to the thermodynamic law described in Gas Accumulator Waterhammer Theory. The law requires a polytropic constant to relate the pressure to the gas volume. An isentropic process should use a polytropic constant equal to the specific heat ratio of the gas (for air it is 1.4). An isothermal process should use a polytropic constant of 1. Typically the process falls in between the two and an average polytropic constant can be assumed (for air the average is 1.2).

The gas in the accumulator is assumed to behave as an ideal gas.

Maximum and Minimum Gas Volumes

If the gas is constrained in some way to a maximum or minimum volume, this can be entered in the optional fields. If a maximum or minimum exists, AFT Impulse will not allow the gas volume to exceed this value. If no data is entered, the volume can grow as large or small as necessary, though the gas volume will still be constrained to be less than the tank volume if Tank Geometry information has been entered.

Interface with Pipe System

The Gas Accumulator can connect into the pipe system in three ways: it can be integral with the pipe, it can be separated by an orifice, or it can be connected by a short pipe.

These options are provided in the Flow Restrictor and Short Connector Pipe areas. If neither option is used, the accumulator is assumed to be attached directly to the pipe with no hydraulic loss.

-

Flow Restrictor - The accumulator is assumed to be separated from the pipe system by an orifice, which causes a hydraulic loss as the liquid flows in and out of the accumulator. The loss is specified by entering a flow area and inflow/outflow discharge coefficient.

-

Short Connector Pipe - This pipe is considered to be short in relation to the other pipes in the system after they are sectioned. If the pipe is short, it can be assumed to react instantaneously with the accumulator. The short pipe accounts for liquid inertia and friction. If a connector pipe exists which cannot be considered short, it should be modeled as an actual AFT Impulse pipe.

The Flow Restrictor and Connector Pipe can both exist in the same accumulator. That is, a flow restrictor can be modeled at the top of a connector pipe, and the effect of both will be included. The loss model for the Flow Restrictor and Short Connector Pipe options is discussed in the Lumped Inertia Pipe with Orifice topic.

Model Relief Valve

On the optional tab on the Gas Accumulator Properties window there is an additional option to model a relief valve on the gas accumulator. This option allows gas to be expelled from the accumulator to prevent pressures from exceeding the relief pressure specified. The relief valve on a gas accumulator is one way and gas will not flow into the accumulator. Once all of the gas has been expelled or the minimum volume is met the accumulator will essentially be a liquid full stagnant region and will not have dynamic system behavior. In other words, once all of the gas is expelled from the gas accumulator it will behave as a loss-less branch if the accumulator is inline or as a dead end if the accumulator is at the end of a pipe.

Special Condition

The special condition for the Gas Accumulator on the optional tab allows the user to set Impulse to ignore the accumulator. See Special Conditions for more information.

As mentioned previously, the gas accumulator acts like a branch junction during steady flow. However, the user can specify that it behaves like a pressure junction by using the Known Initial Pressure option. Why would one want to do this? The most obvious case is where the gas accumulator is modeling a pressurizer type of component in a closed system. A pressurizer is sometimes called an expansion tank or accumulator. The main purpose is to provide thermal expansion volume when the temperature of the process fluid changes. Sometimes these tanks are open to the atmosphere, in which case a Surge Tank would be a better choice than a gas accumulator. When a pressurizer is modeled as a gas accumulator, there will typically be no other pressure type junctions in the system. In fact, the pressurizer is the component which controls the static pressure on the system during steady-state operations. However, during transients the pressure will change. Thus there is a need to allow a gas accumulator to act as a pressure junction during the steady-state, and then like a normal gas accumulator during the transient, as can be done with the Known Initial Pressure option. When the accumulator is a pressurizer during steady-state, it has zero net flow. The pressure entered will be the steady-state static system pressure.

The gas accumulator junction can also be used with the Known Pressure in Steady Flow option to represent a closed tank with a known steady state pressure. In this case the steady state flow to the gas accumulator junction will be non-zero, and a caution will be given at run-time.

Graphing Gas Accumulator data

You can track the gas volume, liquid volumetric and mass flowrate, gas pressure, and liquid height in the accumulator by selecting these options in the Output Junctions panel of the Pipe Sectioning and Output group. These parameters can be graphed or reviewed in the Output window.