Optional Input for Pipes

The Initial Flow Guess for a pipe can be specified. An appropriate initial guess can decrease the number of iterations required to arrive at a converged solution. This initial guess will only affect the steady-state solution process.

The Solver generates initial guesses on its own, which is usually sufficient to get the Solver going in the right direction so a converged solution results. If this is not the case, user defined guesses can help obtain a solution.

Stagnant Region Steady-State Pressure

You can specify a reference pressure in a pipe that will be closed during steady-state which will be used for the transient simulation. Only specify one pressure per stagnant region or you will receive an error stating there is more than one stagnant pressure defined. A single stagnant pressure will allow Impulse to calculate the pressures in the region with hydrostatic pressure differences due to elevation change being taken into account.

A design factor can be used to add safety margins into the hydraulic analysis. For pipes, two design factors exist:

-

Pipe Friction: friction factor is multiplied by the design factor assigned to the pipe.

-

Pipe Fittings & Losses: total loss factor (K factor or Equivalent Lengths) is multiplied by the design factor assigned to the pipe.

Note: The Partially Full Pipe feature should be used with caution. Improper use will result in incorrect calculations or conclusions. Verify that all requirements below are met when using this feature.

The checkbox for "Pipe Can Be Partially Full Along Length" enables an input field for "Percent Full Initially" which defaults to a value of 100%. Normally, Impulse operates under the assumption that all pipes are liquid full as stated in the Engineering Assumptions, and cannot model the filling or draining of the entire system. The Partially Full Pipe feature allows limited modeling of filling or draining of one individual pipe when connected to certain junctions.

Requirements & Assumptions:

-

Only applies to pipes that are connected to an Air Valve, Spray Discharge, Valve specified as an Exit Valve with ambient conditions, or an Assigned Pressure boundary condition specified with ambient conditions.

Note: Ensure that the steady-state pressure at the Air Valve is above the cracking pressure, otherwise Impulse may report a Warning and artificial transient.

-

The pipe must be sloped with one end higher in elevation than the other.

-

The connected junction must be located at the high point. The pipe will drain from the end with the higher elevation.

-

Length refers to the axial length of the sloped pipe, and the liquid-gas interface is assumed to be perpendicular to the pipe wall. This feature does not model a radial percentage of pipe volume and is not intended to be used with horizontal pipes.

-

The pipe cannot have intermediate elevations.

-

Application of the Partially Full Pipe cannot extend or chain to other downstream/upstream pipes in the system. The tracking of the liquid full percentage is only valid in the given pipe.

Overall, selecting this feature implies that one end of the pipe is connected to a junction at its higher elevation endpoint which allows gas to flow in, thus allowing the pipe to drain. Sustained draining for a volume larger than the pipe will violate Impulse's liquid full assumption and the scope of the Partially Full Pipe feature.

Functionality:

-

Disabled - If the option is not enabled, the pipe will always be assumed to be liquid full.

-

Equal to 100% - If the option is selected, and the entry is 100%, it means the pipe is initially 100% full, but can drain if backflow occurs at the high elevation endpoint. This could occur after a pump trip for example.

-

Less than 100% - If the option is selected, and the entry is less than 100%, it means the pipe is initially partially full, and can drain or fill based on the transient simulation. This is only valid when the steady-state condition for the pipe is such that there is no flow, since if there were flow in that pipe during steady-state, the pipe would not be partially full.

Graphing:

Before running the model it is advised to update the Output Pipe Stations item in Analysis Setup to save All Stations for any Partially Full Pipes. When one of the pipes in the model has the Partially Full Pipe feature enabled there will be an additional four graphing parameters available from the Transient Pipe graph type. Graphing any of the stations will produce the same graph since the Partially Full Pipe parameters inherently apply to the entire pipe and not just a single station.

-

Liquid Distance Along Partially Full Pipe - axial distance of the liquid-gas interface

-

Liquid Elevation in Partially Full Pipe - elevation of the liquid-gas interface based on the pipe slope and connected junction elevations

-

Liquid Percent in Partially Full Pipe - percent of the pipe that is liquid full

-

Liquid Station in Partially Full Pipe - the y-axis will show station numbers indicating which are considered liquid-full

Accuracy:

Modeling more sections in the Partially Full Pipe will result in better accuracy. At least two sections should be used, and more if possible. This is because Impulse will model each section in the pipe as either completely liquid full or empty. Therefore, more sections in the Partially Full Pipe will allow Impulse to more precisely determine the liquid level.

A single pipe object can be specified as a number of parallel pipes. When multiple pipes are defined, the parameters in the Pipe Properties window represent only one of the parallel pipes.

The inlet and exit elevations of a pipe are equal to the elevations of the upstream and downstream junctions. The pipe elevation is assumed to vary linearly between the junctions. In other words, the pipe is assumed to be perfectly straight.

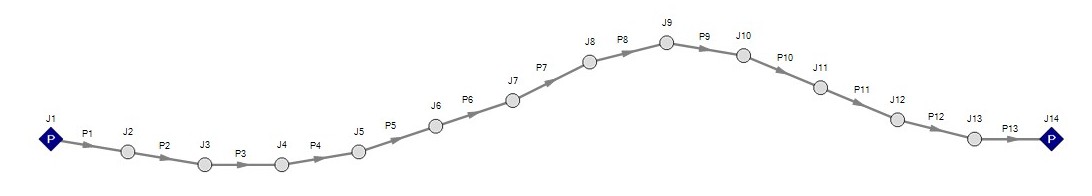

Modeling a large number of elevation changes with straight pipes would require a large number of junctions, as shown below:

Figure 1: Accounting for elevation changes with many pipes and junctions

This is tedious and not required for overall hydraulic calculations - only the elevation change across a (fluid full) pipe is needed. However, intermediate pressure results along the pipe will be affected.

For example, Figure 1 shows elevation extremes both lower and higher than the elevations at the ends of the pipeline. Low points may exceed maximum allowable pressures, and high points could drop below vapor pressure. If this is modeled as a single straight pipe these issues would not be easily identified. In fact, if these pipes were replaced with a single pipe it would show no elevation change at all!

Instead of using a large number of pipes, these effects can be accounted for in a single pipe using intermediate pipe elevation feature.

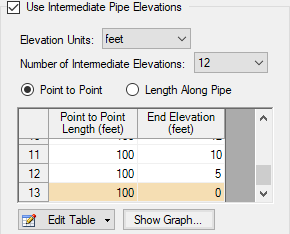

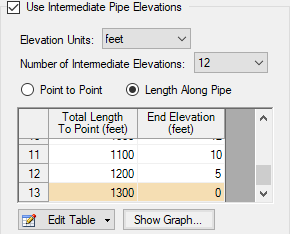

With length defined, check Use Intermediate Pipe Elevations, choose the elevation units, the number of intermediate elevations (a 2 segment pipe has 1 intermediate elevation), and whether the entered values are Point to Point or Length Along Pipe.

Figure 2: Intermediate Elevations - Identical Profiles defined with both methods

AFT Impulse will ensure the total length matches the length on the Pipe Model tab. It does so by fixing the length of the final section to the difference between the sum of the lengths in the table and the actual length entered by the user. The end elevation is also fixed by the downstream junction. If the user later modifies the downstream junction elevation, the pipe’s final elevation section will be automatically updated. The maximum number of rows available in this table can be changed in User Options.

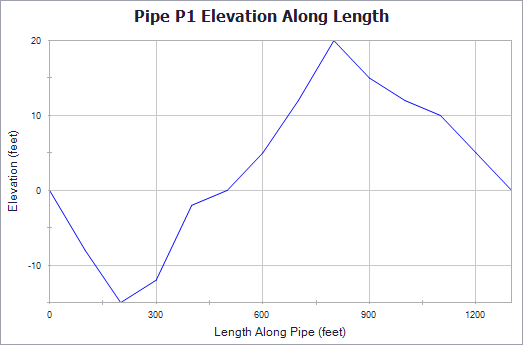

After the intermediate elevations have been entered, a graph showing the data can be displayed. Below is the profile graph of the pipe described above.

Figure 3: Intermediate Elevation Graph