PAT Operation During Decoupling

The PAT transitions between the turbine and decoupled operating conditions in two situations: when manually decoupled or whenever the power generated is equal to zero. In Impulse, the PAT can never recouple after becoming decoupled.

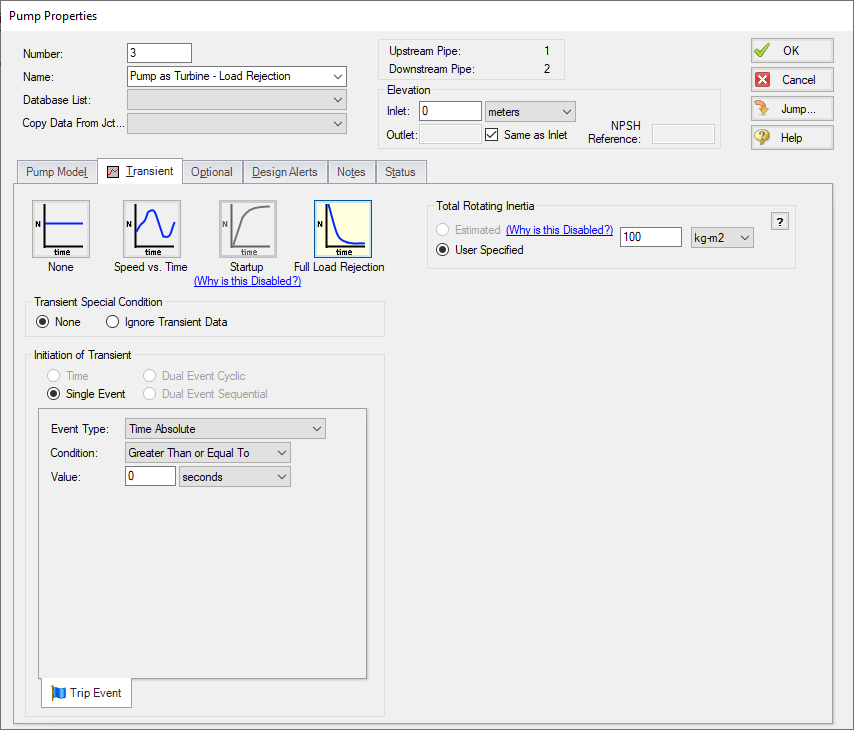

The first transition from coupled to decoupled is referred to as Full Load Rejection and can be set as a transient event in the Transient tab of the Pump Properties window.

Figure 1: Transient tab of the Pump Properties window for a PAT showing the Full Load Rejection option.

When this transient event is initiated, the PAT is immediately uncoupled from its motor, the speed is allowed to change as dictated by the fluid, and the PAT speed is determined for each time step using the below equation. Here time step i is the current time step, i+1 is the next time step, N is the impeller speed (in RPM), P is the power imparted on the impeller by the fluid, and I is the total rotating inertia of the PAT impeller and shaft.

This equation is the same equation used to predict PAT speed when decoupled.

During a full load rejection, the PAT will rapidly spin up as the generator is no longer resisting the torque applied on the impeller by the fluid. The flow rate through the PAT also slows down as the PAT shifts from operating in the Turbine Zone to operating at the No Load point.

The second transition from coupled to decoupled occurs when the PAT reaches the No Load point due to other transient events in the system. This transient event is always ready to occur regardless of the transients defined for the PAT. When the flow rate through the PAT becomes low enough such that zero power is generated by the pump, the pump will immediately become uncoupled from the motor and become free-spinning with its speed determined by the equation described above.

Related Topics

Related Blogs