Heat Tracing Flux Based On Wire Turns and Length

The Convective Heat Transfer with Heat Tracing model requires additional information to represent the thermal effect of a heat tracing.

xStream allows users the ability to model Heat Tracing by either entering the heat flux directly, or by providing information on the number of turns and power per unit length of wire, which xStream will use to determine the heat flux as described below.

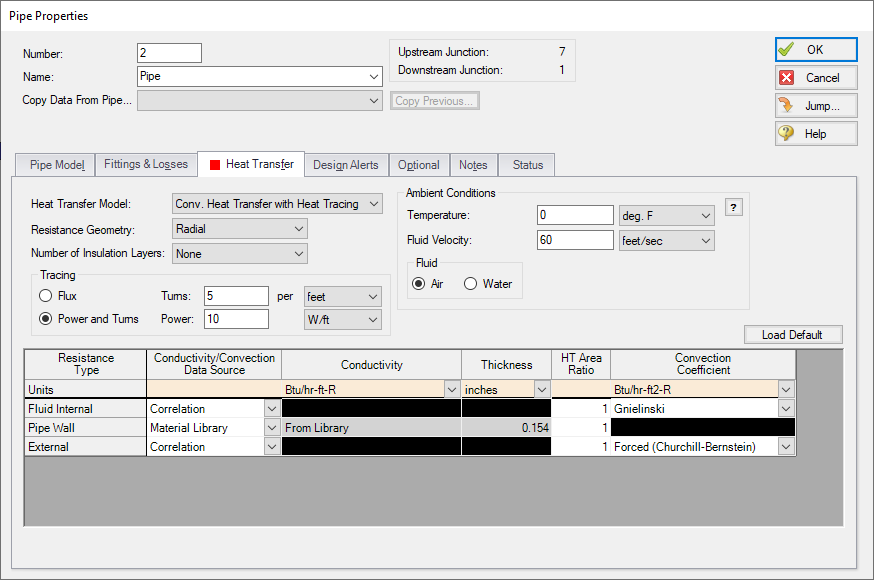

Figure 1: Pipe Properties window with the Conv. Heat Transfer with Heat Tracing model enabled

Power and Turns - Detailed Discussion

When you select the option to model Heat Tracing based off a heated wire, xStream models that heat flux based on the theory described below.

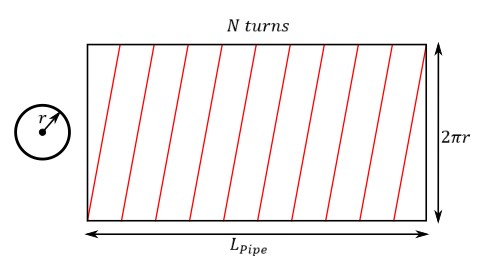

Figure 2: Wire tracing geometry

Length of Wire

First, it may be necessary to determine the length of the wire itself, based on a number of turns.

-

N - total number of turns on the pipe

-

n - number of turns per unit length

-

LPipe - total length of the pipe

-

r - external radius of the pipe

-

LWire - length of the wire

-

LTurn - length of one wire turn

The above figure shows a pipe with heat tracing that has been "split open" and laid into a flat rectangle to make these equations more intuitive.

The total turns and turns per length are related by the pipe length:

Each turn of the wire creates a right triangle on the "flattened" pipe, so we can find the length of each segment by the Pythagorean theorem.

The total length of the wire is related to the number of turns and the segment length.

Incorporating this relationship and rearranging:

Using the number of turns per unit length:

or:

Flux of Wire

With the length of the wire found, the flux based on power per length can be found.

-

PTotal - total power usage of the wire, along the entire pipe length

-

p - power per unit length

-

Q'' - heat flux

-

A - area heat flux is applied to

The heat flux is defined as the heat delivered per area. Here, we assume that the "total power" used by the heat trace is equivalent to the total heat delivered. Therefore:

The total power is equal to the power per length times the length, and area is related to pipe geometry:

Substituting in for LWire:

Simplifying: