Process Steam System - GSC (English Units)

Process Steam System - GSC (Metric Units)

Summary

The objective of this example is to demonstrate how multiple goals and variables are used in the GSC module to achieve an objective.

Note: This example can only be run if you have a license for the GSC module.

Topics Covered

-

Defining the Goal Seek and Control group

-

Setting Variables and Goals

-

Using Group Max/Min Goals

-

Linking Variables

-

Interpreting Goal Seek and Control output

Required Knowledge

This example assumes the user has already worked through the Beginner: Air Heating System example, or has a level of knowledge consistent with that topic. You can also watch the AFT Arrow

In addition the user should have worked through the Beginner: Heat Transfer in a Pipe - GSC example.

Model Files

This example uses the following files, which are installed in the Examples folder as part of the AFT Arrow installation:

Problem Statement

For this example, we will use the GSC module to determine the supply pressure necessary to meet a minimum delivery pressure of

Step 1. Start AFT Arrow

From the Start Menu choose the AFT Arrow 9 folder and select AFT Arrow 9.

To ensure that your results are the same as those presented in this documentation, this example should be run using all default AFT Arrow settings, unless you are specifically instructed to do otherwise.

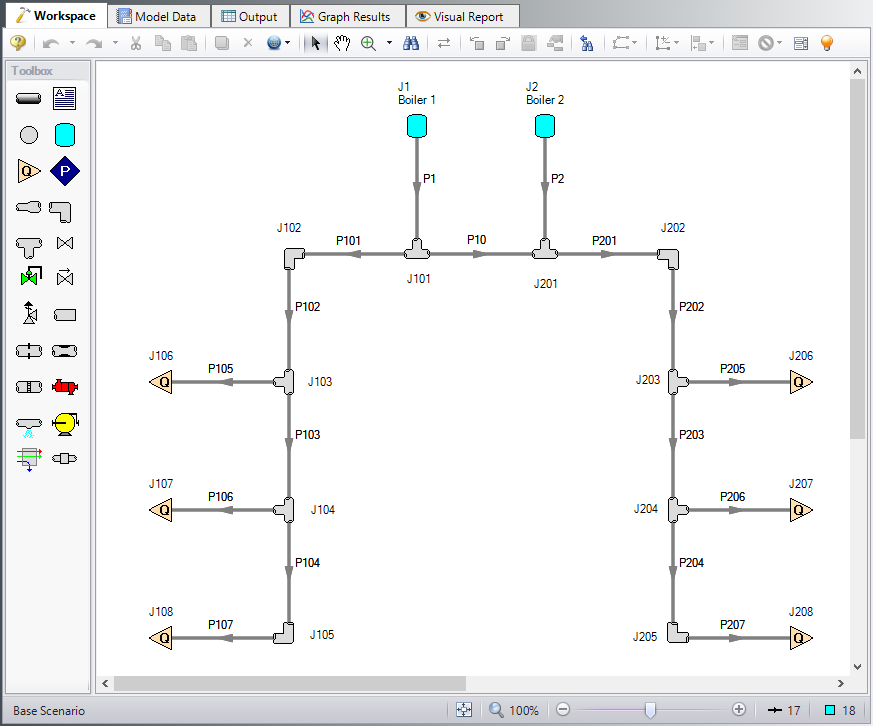

Open the US - Process Steam System.aro example file listed above, which is located in the Examples folder in the AFT Arrow application folder. Save the file to a different folder. This is the only scenario needed for this example, so right-click the Base Scenario and select Delete All Children. The workspace should look like Figure 1:

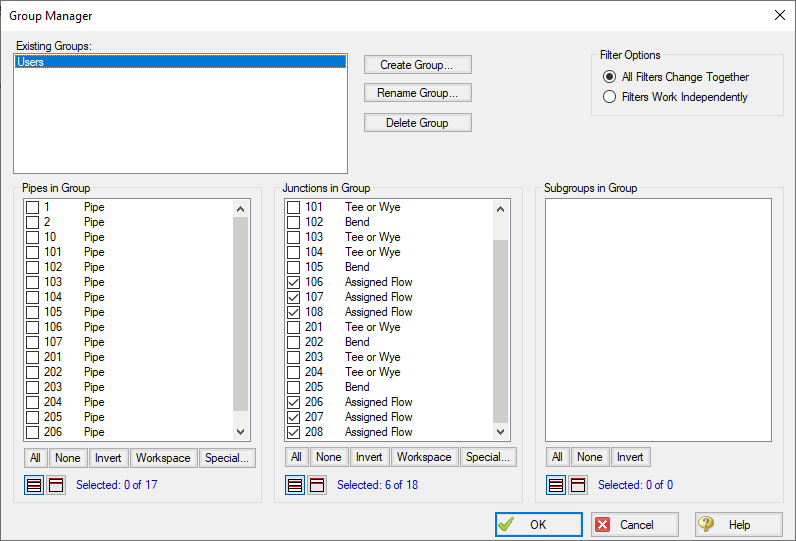

Step 2. Create a Group

In order to use the Group Max/Min goal type, the junctions or pipes included in the goal must be added to a group. To create a group, select the Groups | Create option from the Edit menu. When prompted, give the new group the name Users and click OK. After naming the new group, the Group Manager will be displayed. Select the new group name from the list, and then select all of the assigned flow junctions from the junction list, as shown in Figure 2. After choosing the assigned flow junctions, click OK on the Group Manager window.

Step 3. Define the Modules Group

Navigate to the Modules panel in Analysis Setup. Check the box next to Activate GSC. The Use option should automatically be selected, making GSC enabled for use.

Step 4. Define the Goal Seek and Control Group

Specify the variables and goals for the model using the Goal Seek and Control group in Analysis Setup.

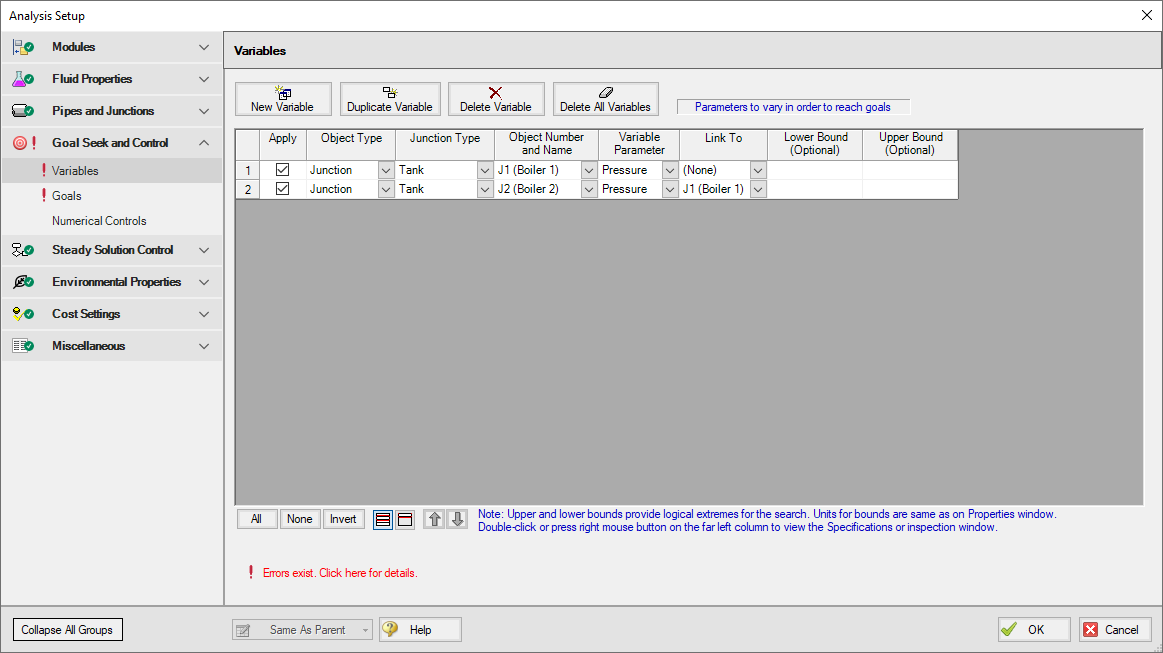

Variables Panel

For this example, we want to find the supply pressures that will give us a specific minimum discharge pressure. We will define the delivery pressures as a single Group Max/Min goal. But that gives us only one goal for two variables. To solve this issue, we will use variable linking. Variable linking allows you to tie multiple variables together, forcing them to be the same. To accomplish this, we will add a constraint to the problem that both of the boiler supply pressures must be the same.

To implement variable linking, add both tank junctions pressures as variables. Then link them together by specifying Boiler 1 (J1) in the Link To column of the Boiler 2 (J2) variable. Enter the data as shown below.

Open the Variables panel, click New Variable, and enter the following variable data:

-

J1 Boiler 1

-

Apply = Selected

-

Object Type = Junction

-

Junction Type = Tank

-

Junction Number and Name = J1 (Boiler 1)

-

Variable Parameter = Pressure

-

Link To: (None)

-

Lower Bound: Leave blank

-

Upper Bound: Leave blank

-

-

Boiler 2 (J2)

-

Apply = Selected

-

Object Type = Junction

-

Junction Type = Tank

-

Junction Number and Name = J2 (Boiler 2)

-

Variable Parameter = Pressure

-

Link To = J1 (Boiler 1)

-

Lower Bound: Leave blank

-

Upper Bound: Leave blank

-

After entering the variable data, the Variables tab in the Goal Seek and Control manager should appear as shown in Figure 3.

Goals Panel

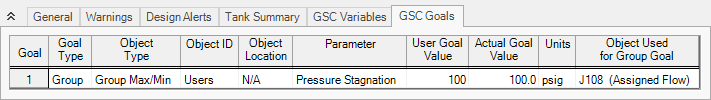

For this example, we will be using a Group Max/Min goal. This type of goal allows a single goal to be applied to a group of objects. Arrow applies a Group Max/Min goal by ensuring the final goal value is either greater than or equal to (Min) or less then or equal to (Max) the specified value. For our example, a Group Max/Min goal will be applied to ensure the minimum discharge pressure at all of the assigned flow junctions is at least

Open the Goals panel, click New Goal, and enter the following goal data:

-

Apply = Selected

-

Goal Type = Group

-

Object Type = Group Max/Min

-

Goal Parameter = Pressure Stagnation

-

Criteria = >=

-

Goal Value = 100

-

Goal Units = psig

-

Object ID = Users

-

Object Location = NA

As variables and goals are added to a model, AFT Arrow will display symbols beside the pipes and junctions that have variables or goals applied to them. The default is a V for variables, and a G for goals. The goal symbol is not displayed next to objects that are part of a group goal, so you will see only the V displayed on the Workspace for this example.

Step 5. Run the Model

Click Run Model on the toolbar or from the Analysis menu. This will open the Solution Progress window. This window allows you to watch as the AFT Arrow solver converges on the answer. Once the solver has converged, view the results by clicking the Output button at the bottom of the Solution Progress window.

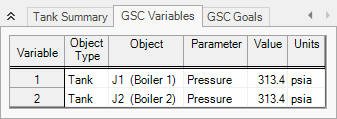

Step 6. Examine the Output

The results of the GSC analysis are shown in the General section of the Output window. The GSC Variables tab shows the final value for the variable parameter, as shown in Figure 4. The GSC Goals tab shows the final value achieved for the goal, as shown in Figure 5.

The GSC module analysis determined the supply pressure required to ensure a minimum delivery pressure of 100 psig at the users is 313.4 psia.