Physical Parameters vs. Monetary Cost

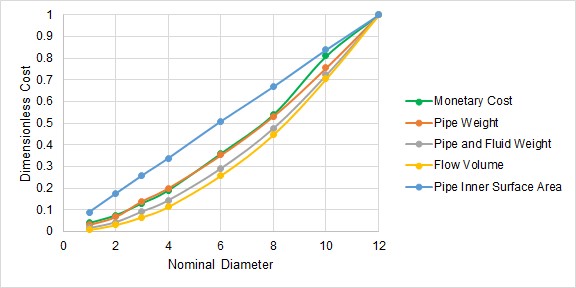

There are four physical parameters that can be maximized or minimized in addition to monetary cost:

-

Pipe Weight

-

Pipe and Fluid Weight

-

Flow Volume

-

Pipe Inner Surface Area

Actual Objective is to Limit the Physical Parameter

Occasionally, the goal of the sizing is to limit the physical parameter. For example, a system to be placed on an aircraft likely has greater emphasis on weight than monetary cost. It is important to keep in mind in such cases that only the pipes are included in the total Objective value. Compressors, valves, or other junctions that contribute to weight are not accounted for. This may affect the ideal sizing.

Using a Physical Parameter to Estimate Cost

There are advantages and disadvantages of estimating cost with a physical parameter.

It is generally far easier to use a physical parameter as cost libraries are not required. Cost libraries are difficult to locate information for, and can be time consuming to create and manage. Avoiding this greatly simplifies the process.

The main disadvantage is that only initial pipe costs can be accounted for. If junctions account for a significant portion of the initial cost, or if the recurring costs from operating them would affect sizing, then this may not result in the best sizing solution.

In general, if the goal is to minimize monetary cost of a system, then monetary information should be supplied. If recurring costs must be included, this is the only reasonable option. However, physical parameters often provide a good estimate of the ideal size for initial cost. It makes sense to start the sizing process with a physical parameter, and proceed to monetary cost as the Objective after larger design issues have been resolved. This is especially true if the potential savings are large.

Figure 1: Comparison of Dimensionless Costs for Schedule 40 ANSI Steel water pipe. RS Means monetary cost closely follows pipe weight in this example.