Stagnation vs. Static Pressure Boundaries

With two exceptions (to be discussed), all pressure-type boundary conditions in AFT Arrow are stagnation. This works very well for things such as large storage tanks or atmospheric boundaries, where the volume associated with a pressure is large and will not change (significantly) with time. These boundaries have no velocity associated with them, and using stagnation pressure is thus appropriate. These boundary conditions are most clearly rendered in AFT Arrow by use of a Tank junction.

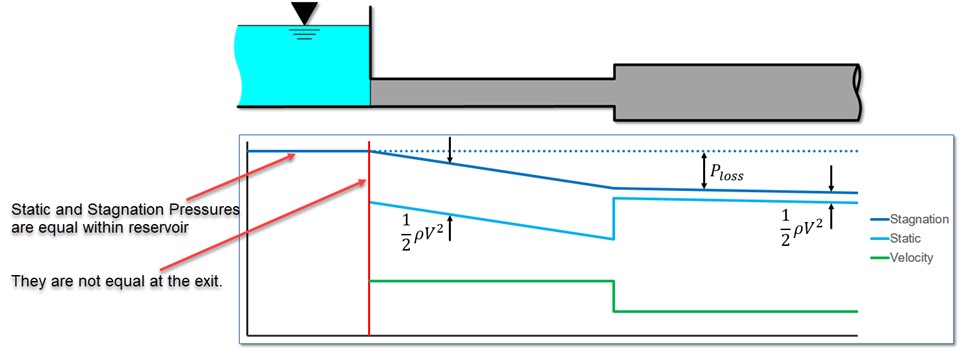

For simplicity, we will discuss this in terms of an incompressible flow example. Consider the reservoir and connected pipe in Figure 1. When the liquid in a reservoir flows into connecting pipes, the static pressure immediately drops due to the increase in velocity.

It is tempting to say that because there is no velocity in the reservoir, then it does not matter whether the reservoir boundary pressure is considered as a static or stagnation pressure because they are equal. This is a misconception. The pressure boundary condition in an AFT Arrow model is applied at the exit of the junction, not within the junction itself. Inside the reservoir, the static and stagnation pressures are the same, but they are not the same at the exit - they differ by the amount of the dynamic pressure.

Note: An incompressible liquid flow example is given because it is easier to discuss, but the principles apply similarly to compressible flow.

Figure 1: Reservoir with one connecting pipe (incompressible flow)

The appropriateness of either stagnation or static pressure as a boundary condition depends on whether there is a velocity associated with the pressure that is specified. Is the pressure in a vessel or large (lower velocity) header, or is it in a pipe somewhere in the middle of a system? If the first, stagnation is more appropriate; if the second, static.

Pressure boundary conditions with no velocity are more common across all piping industries, and are usually appropriate. However, this is not always the case.

When to Use Static Pressure

Now let's consider the application of a true static pressure boundary condition. A static boundary condition has a unique velocity associated with it. The Bernoulli equation, which in this integrated form applies only to incompressible flow, is given by:

From this equation it can be seen that application of the static pressure is not sufficient to specify location 1. The velocity and elevation is also required. Note that though the equation above is only applicable for incompressible flow, the general concept is applicable for compressible flow.

In AFT Arrow, elevation data is entered for junctions. The pipes adopt the elevation of the junction to which they are connected.

But where does the velocity information in the Bernoulli equation come from? One might respond that it can be obtained from the flow rate. But this raises another question: what if the flow rate isn’t known? Put another way, what if the flow rate is what we are solving for?

Because the stagnation pressure combines the static pressure with the velocity information (in the form of Mach number, see Stagnation Pressure definition), when the user supplies a stagnation pressure boundary condition AFT Arrow can avoid the need for an associated velocity condition at location 1. A stagnation pressure boundary can thus be supplied to multiple pipes that might have different velocities. That is why the same Tank junction can connect with multiple pipes.

However, if the user specifies a static pressure as the boundary condition, a unique velocity (or Mach number) must be supplied. Thus it is only possible to connect a static pressure to a single pipe with a unique velocity.

Important: A static pressure boundary has a unique velocity (and Mach number) associated with it, and can thus connect to only one pipe.

Where would one find a static pressure boundary? The best example is when the boundary condition is inside a pipe. A pipe system model can start and end anywhere it is convenient for the user. It may be convenient to not start the model at the physical boundary (such as a tank) but at a particular location in the pipe system. This could be, for example, at the location of a pressure measurement. Or it could be at the boundary of the pipe system for which your company is responsible, with another company responsible for what is on the other side of that boundary.

If one needs to model such a situation, the Assigned Pressure junction allows one to model either a static or stagnation pressure. The default stagnation pressure allows connection of up to 25 pipes. If static pressure is chosen, only one connecting pipe is allowed.

Static Pressure at Pressure Control Valves

Another example of static pressure is at pressure control valves. For pressure control valves (i.e., PRV’s and PSV’s) the default control pressure is static pressure. The reason is that the measured pressure that provides feedback to the controller will typically be a static pressure measurement. You have the option of modeling pressure control valves as either static or stagnation pressure.