SSL Pump De-Rating

(SSL Module Only) When centrifugal pumps are pumping slurries the solids in the slurry can cause decreased pump performance. This is known as de-rating, as the process involves reducing the pump head curves provided by manufacturers which are based on clear water.

The SSL module offers three methods to estimate pump de-rating. The first is based on a standard published by the Hydraulic Institute in 2016. In AFT Fathom it is called the “ANSI/HI Standard 12.1-12.6-2016ANSI/HI Standard 12.1-12.6-2016, Rotodynamic (Centrifugal) Slurry Pumps, 2016, published by Hydraulic Institute, 6 Campus Drive, Parsippany, New Jersey, USA ” method. The second is based on the Warman method. The third allows the user to define a CH, CQ and CE rather than having them calculated.

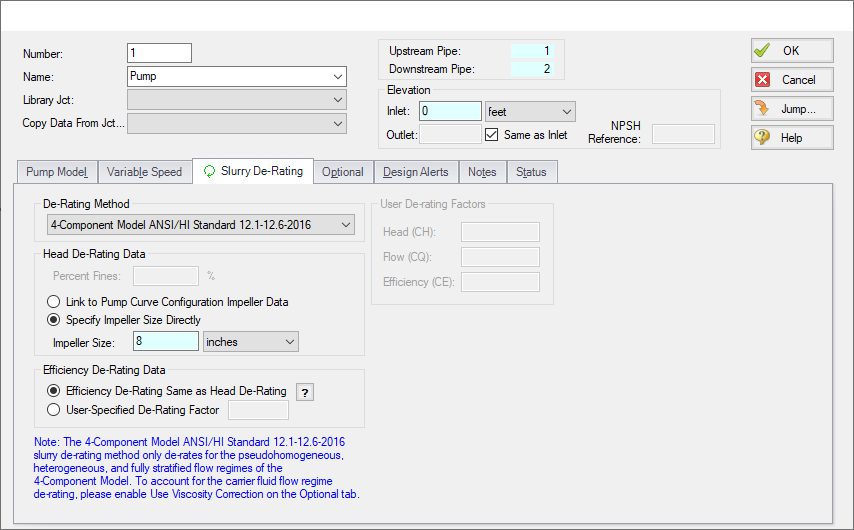

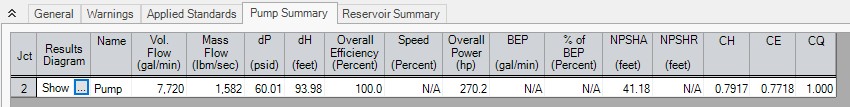

When the SSL module is used, a new tab appears on the Pump Properties window called Slurry De-Rating (Figure 1). Here the user can choose the de-rating method. The de-rating factors are shown in the Output window Pump Summary as CH (for head correction) and CE (for efficiency correction). Figure 2 shows the Pump Summary with correction factors displayed. If you do not see them in your Output you can add them to the Pump Summary in the Output Control window opened from the Tools menu.

Figure 1: Slurry De-Rating tab on Pump Properties Window lets user estimate reduced pump performance due to solids

Figure 2: Pump de-rating factors CH and CE are shown in Output window Pump Summary

Theory of Pump De-Rating

The head reduction for slurry pumps is based on ANSI/HI Standard 12.1-12.6-2016, page 52, Figure 12.3.2.7 (not shown here). Correction factors for solids density, solids concentration and percent of fine particles are applied per the standard. This figure and methodology is the same as found in Wilson, et al. 2006 on page 243.

The Warman Method is in use in industry but is not widely available. The method used in AFT Fathom is based on a white paper by Walker, C. I.,Walker, C. I., The effect of settling slurries on pump performance, undated, Warman International. Undated, page 2, and uses a correction factor for impeller size. Cm is the solids mass concentration of the slurry in terms of percent mass.

The 4-Component Model option is a modified form of ANSI/HI Standard 12.1-12.6-2016 by GIW Industries Inc.Visintainer, Robert. “GIW 4-Component Model Summary 2022-09-03.” GIW Industries Inc., 2022. [Online]. Available: https://www.ksb.com/en-us/services/service-for-slurry-pumps/hydraulic-lab intended for use with the 4-Component Slurry Model. The head reduction is given by the following equation.

Where rh is the total percent head reduction factor (i.e. 1 percent de-rate is 1.0) and rh,f, rh,p, rh,h, and rh,s are the contributions of the carrier fluid viscosity, pseudo-homogeneous fraction, heterogeneous fraction, and fully stratified fraction, respectively.

For viscosity below 20 centipoise, GIW guidelines state that rh,f can be assumed to be zero. Above 20 centipoise, ANSI/HI 9.6.7-2021ANSI/HI Standard 9.6.7-2021, Rotodynamic Pumps - Guideline for Effects of Liquid Viscosity on Performance, 2021, published by Hydraulic Institute, 300 Interpace Parkway, Building A, 3rd Floor, Parsippany, New Jersey, USA. should be used to calculate this term.

Note: The Viscosity Correction term rh,f is not automatically applied when pump slurry de-rating is in use. To incorporate this term, Use Viscosity Correction must be enabled in the Optional tab. That option alone determines whether rh,f is calculated and the recommended 20 centipoise threshold is not used.

The equations for the other components take the following general form where D2 is pump diameter in meters, DREF is 1.0 m, SS is the solid specific gravity, Sx is the mixture specific gravity for each component, Cv is the volumetric concentration of solids, and Xx is the fraction of solids associated with each component. S1 is equal to 0.5 times D2/DREF and S2 is 0.4.

This results in the following three equations:

Where A”, B”, and C” are empirical parameters and d50p, d50h, and d50s are the average particle sizes in mm of the pseudo-homogenous, heterogeneous, and fully stratified fractions, respectively. CH is determined from rh with the following expression.

Related Topics

Related Examples