When Goals Cannot Be Achieved

(GSC Module Only) In some cases the GSC module may not be able to achieve a goal. This can happen for the following reasons:

-

A goal is not physically realistic

-

A better starting point is needed for the input values assigned as GSC Variables

-

Hydraulic solution tolerances or optimizer numerical parameters require adjustment

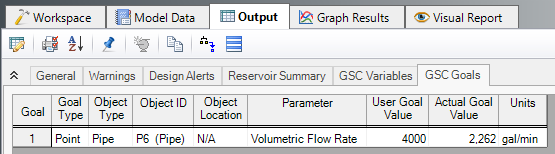

In such cases, the goal will not be satisfied in the results. In other words, the Actual Goal Value and User Goal Value will differ (Figure 1).

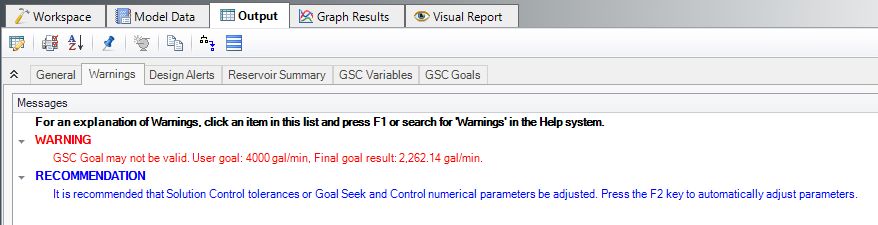

In all cases the user will be warned when goals were not met. Figure 1 shows the Output window with such a warning.

Figure 1: Warning display in Output window when a goal cannot be met

Physically Unrealistic Goals

It may be possible that a goal is not achievable because it is not physically possible. For example, a pump may be too small to satisfy a flow rate goal at some pipe.

To determine whether a goal is unrealistic, try changing the goal and rerunning the model. If the goal can be met in some cases and not others, this is an indicator that the original goal was unrealistic.

Better Starting Point Needed

In some cases the goal may be so far away from the original model that the GSC module has difficulty finding a solution. This is not common, but it is worth trying to adjust the starting point of parameters which are being varied.

Changing Control Parameters

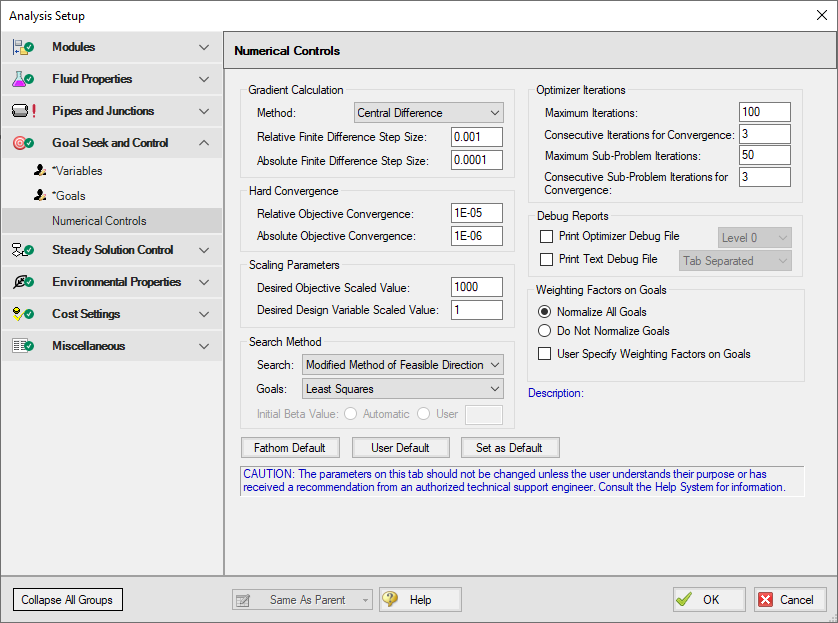

The Numerical Optimizer determines goal search directions by approximating a gradient based on perturbed variable values. By default it uses a central difference approximation, but forward difference can also be used. If the hydraulic solution is not converged to a sufficiently small tolerance, the gradient approximation will not be sufficiently accurate and hence a good search direction cannot be obtained. The end result is that the goal seeking fails.

There are two general area that can be changed in such cases: the hydraulic solution tolerances in the Steady Solution Control group and Numerical Controls panel in Analysis Setup.

In the next few sections recommendations on how to manually change these parameters will be given. However, before making a manual change it is worthwhile to try the automated parameter adjustment feature.

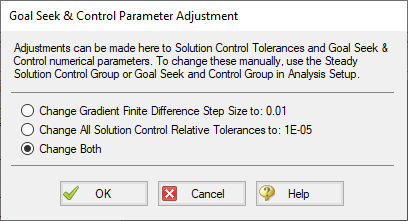

Figure 1, bottom picture, shows the warning when a goal is not met, and also shows a recommendation and suggest pressing the F2 key. When doing so, a window appears as shown in Figure 2. This window will offer up to three options for automatic parameter adjustment. Accepting the default values is typically a good starting point. Click OK, and rerun the model.

The purpose of the window shown in Figure 2 is to simplify making common changes to resolve goal seeking problems.

Figure 2: When goal seeking fails, pressing the F2 key will show this window which allows the user to automatically implement recommend numerical parameter adjustments

Caution: The user should be very cautious in manually changing parameters in the Steady Solution Control Group and Numerical Controls panel. Making changes without a good understanding of the parameters involved can lead to incorrect results.

-

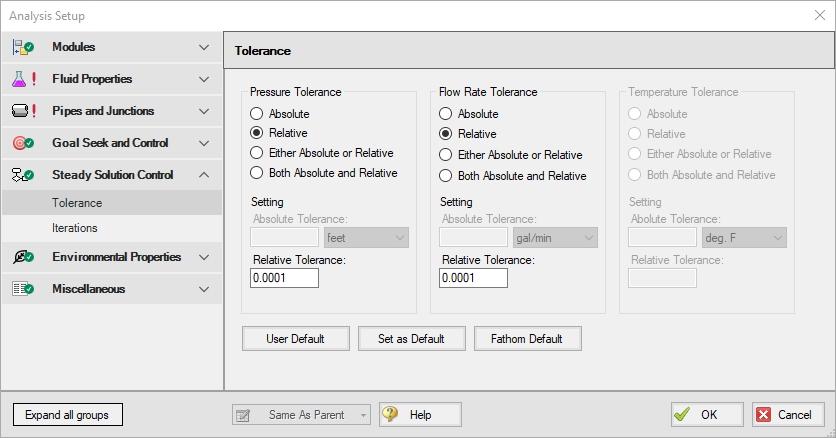

Changing Tolerance on Tolerance panel - By default AFT Fathom uses Relative Tolerance criteria set to 0.0001 (see Figure 3). Goal seeking convergence can sometimes be improved by reducing these values to 0.00001 or 0.000001.

-

See Iterations panel for a more in-depth discussion.

-

-

Changing Goal Seeking Numerical Controls - Figure 4 shows the Numerical Controls panel in Analysis Setup. The most useful parameter one can adjust is the Relative Finite Difference Step Size. Using values between 0.01 and 0.001 are recommended. In some cases using a value as high as 0.1 may be tried.

Figure 3: Reducing tolerance may resolve goal seeking difficulties

Figure 4: Changing certain numerical control parameters in the Numerical Controls panel in the Goal Seek and Control group may resolve goal seeking difficulties