Control Valve (Metric Units)

Summary

This will walk you through a simple calculation to calculate a pipe size for a control valve system. Water will be flowing from a reservoir on a hill down to another reservoir. The pipe must be sized correctly to allow

Topics Covered

-

Using flow control valves

-

Entering and changing pipe size data

Required Knowledge

This example assumes the user has already worked through the Beginner: Three Reservoir Problem example, or has a level of knowledge consistent with that topic. You can also watch the AFT Fathom Quick Start Video Tutorial Series on the AFT website, as it covers the majority of the topics discussed in the Three-Reservoir Problem example.

Model File

This example uses the following file, which is installed in the Examples folder as part of the AFT Fathom installation:

Step 1. Start AFT Fathom

From the Start Menu choose the AFT Fathom 12 folder and select AFT Fathom 12.

To ensure that your results are the same as those presented in this documentation, this example should be run using all default AFT Fathom settings, unless you are specifically instructed to do otherwise.

Step 2. Define the Fluid Properties Group

-

Open Analysis Setup from the toolbar or from the Analysis menu.

-

Open the Fluid panel then define the fluid:

-

Fluid Library = AFT Standard

-

Fluid = Water (liquid)

-

After selecting, click Add to Model

-

-

Temperature = 21 deg. C

-

Step 3. Define the Pipes and Junctions Group

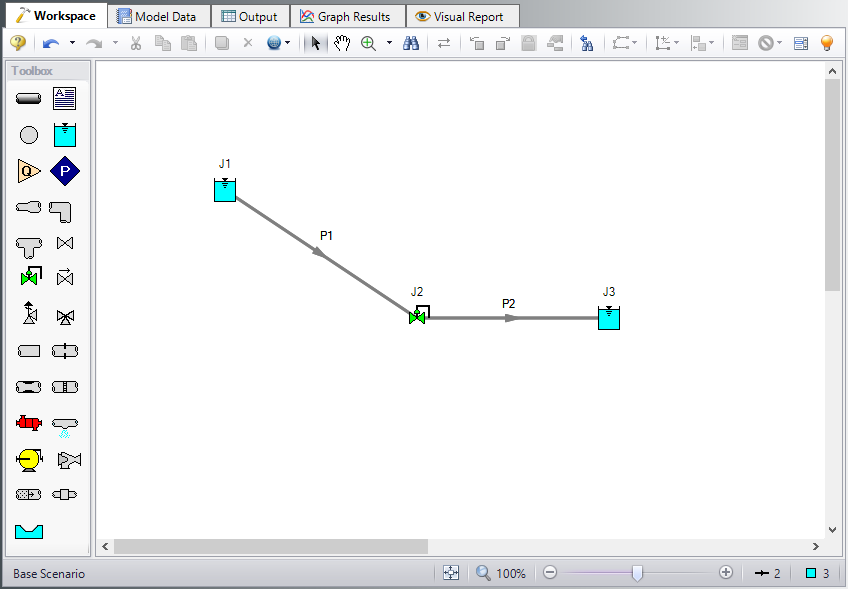

At this point, the first two groups are completed in Analysis Setup. The next undefined group is the Pipes and Junctions group. To define this group, the model needs to be assembled with all pipes and junctions fully defined. Click OK to save and exit Analysis Setup then assemble the model on the workspace as shown in the figure below.

The system is in place but now we need to enter the properties of the objects. For this example, we need to find the correct pipe size but we are limited to STD (schedule 40) pipe sizes. We need to use our engineering judgment to take an initial guess at the pipe size for

Pipe Properties

-

All Pipes

-

Pipe Material = Steel - ANSI

-

Pipe Geometry = Cylindrical Pipe

-

Size = 3 inch

-

Type = STD (schedule 40)

-

Friction Model Data Set = Standard

-

Length = 30 meters

Junction Properties

-

J1 Reservoir

-

Name = Upper Reservoir

-

Liquid Surface Elevation = 12 meters

-

Liquid Surface Pressure = 0 barG

-

Pipe Depth = 0 meters

-

J2 Control Valve

-

Inlet Elevation = 3 meters

-

Valve Type = Flow Control (FCV)

-

Control Setpoint = Volumetric Flow Rate

-

Flow Setpoint = 57 m3/hr

-

J3 Reservoir

-

Name = Lower Reservoir

-

Liquid Surface Elevation = 3 meters

-

Liquid Surface Pressure = 0 barG

-

Pipe Depth = 0 meters

ØTurn on Show Object Status from the View menu to verify if all data is entered. If so, the Pipes and Junctions group in Analysis Setup will have a check mark. If not, the uncompleted pipes or junctions will have their number shown in red. If this happens, go back to the uncompleted pipes or junctions and enter the missing data.

Step 4. Run the Model

Click Run Model on the toolbar or from the Analysis menu. This will open the Solution Progress window. This window allows you to watch as the AFT Fathom solver converges on the answer. This model runs very quickly. Now view the results by clicking the Output button at the bottom of the Solution Progress window.

Step 5. Examine the Output

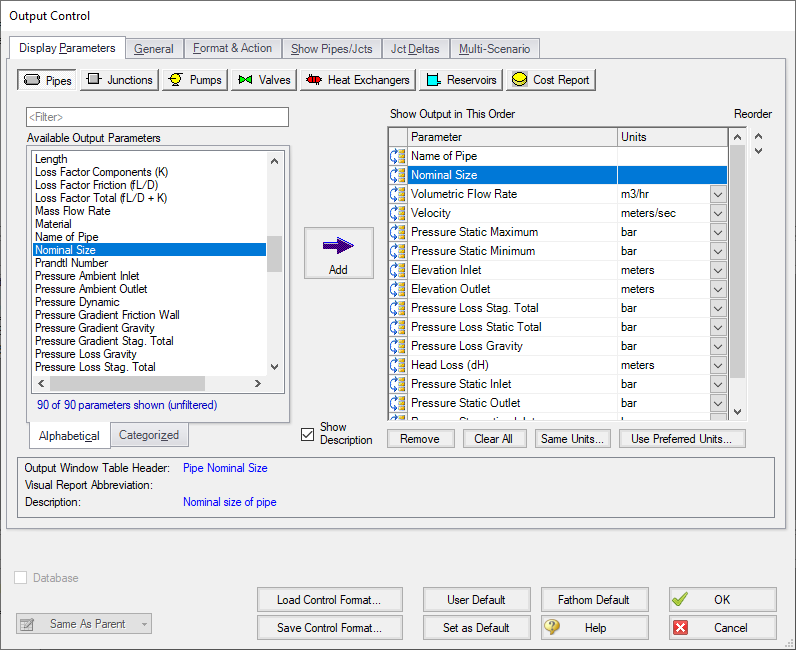

Open the Output Control window by selecting Output Control from the Output toolbar or Tools menu. This window allows the user to specify the output from the Fathom simulation. The window starts with a default set of output parameters which you are free to change.

In this example, we want to review the effects of changing the nominal pipe size. To simplify this, lets add this parameter to the output.

-

From the Pipes output list, select the parameter Nominal Size in the list on the left.

-

Click Add (or double-click the parameter), which adds the parameter to the list on the right.

-

Use the Reorder buttons (in the upper right) to move the Nominal Size up so that it becomes the second parameter in the list (see Figure 2).

-

Click OK.

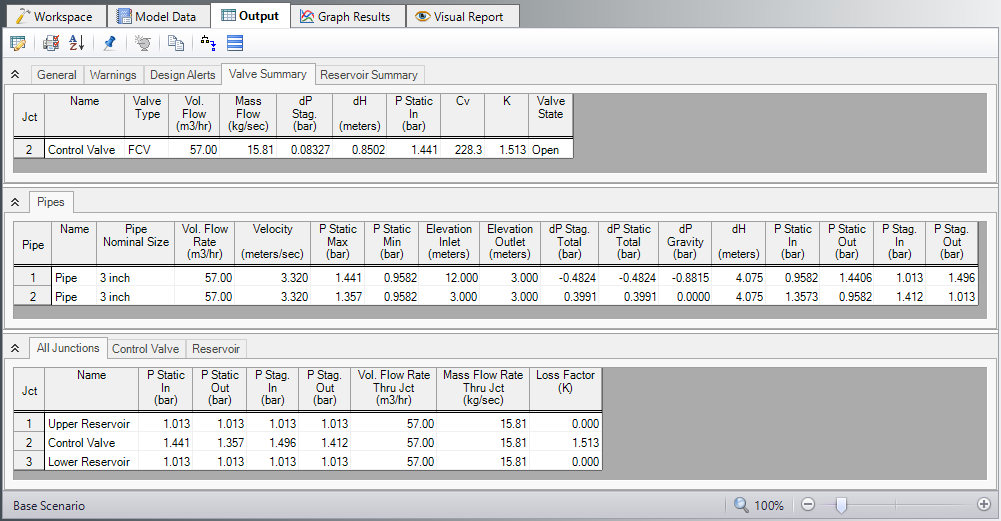

The Output window contains all the data that was specified in the output control window. The output is shown in Figure 3. In the summary window, there is a Valve Summary tab. Select this tab. You can see that the flow control valve achieved the flow rate of

Step 6. Change Pipe Sizes

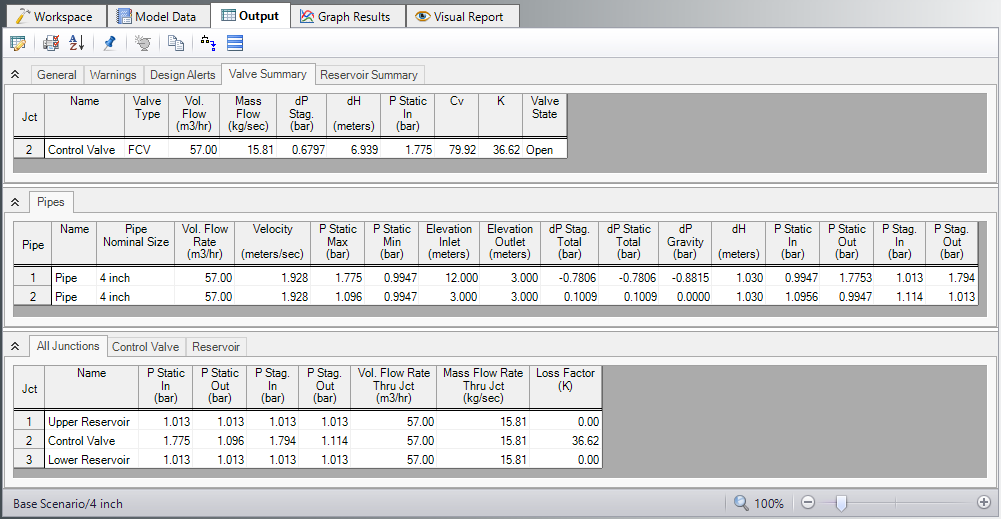

Go back to the Workspace and change the pipe properties to a new pipe size. By trial and error, you can determine that by using 4 inch for both pipes, a pressure drop of

Conclusion

To meet the system requirements, use 4-inch pipe.