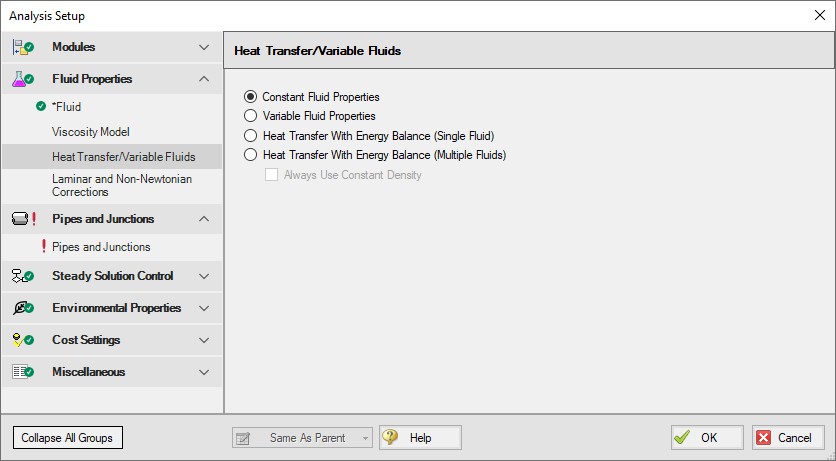

Heat Transfer/Variable Fluids Panel

The Heat Transfer/Variable Fluids panel, shown in Figure 1, allows users to how the fluid properties will vary. The fluid selected on the Fluid panel must have data entered for the heat transfer parameters, such as specific heat, for the Heat Transfer options to be available, as is discussed further in the Custom Fluids topic.

Note: When heat transfer is enabled only Newtonian fluids can be modeled

-

Constant Fluid Properties - all fluid properties are the same for every pipe and are as specified on the Fluid panel. Note that non-newtonian viscosity models will still cause the viscosity to vary if the constant fluid properties option is selected.

-

Variable Fluid Properties - the values for density and viscosity on the Fluid panel are the default fluid properties. You can enter different fluid property values, if desired, for any pipe in the Pipe Properties window. This does not mean that fluid properties can vary on their own in the model - they are constant in each pipe and must still be directly specified by the user.

-

Heat Transfer With Energy Balance (Single Fluid) - all fluid properties are determined dynamically during the run based on the most recent solution for temperature and pressure and are thus inherently variable. Only one fluid is used in the model. Additional inputs will be required in the pipes and junctions to model heat transfer.

-

Heat Transfer With Energy Balance (Multiple Fluid) - all fluid properties are determined dynamically during the run based on the most recent solution for temperature and pressure and are thus inherently variable. Piping loops with different fluids can be modeled using Fluid Groups to input multiple fluids into the model, such as to represent different sides of a heat exchanger. However, dynamic mixing of fluids is not supported. Additional inputs will be required in the pipes and junctions to model heat transfer.

Always Use Constant Density - only applicable to Variable Fluid Properties and Heat Transfer With Energy Balance (Single Fluid). This option forces the fluid density to remain constant throughout the model. This can be convenient when density variations due to temperature are minimal but viscosity changes are significant. Enabling this option has only minimal impact on results in these cases, and can greatly simplify and clarify the head and gradeline values which would otherwise change by some minimal amount.

Figure 1: Heat Transfer/Variable Fluids panel

Related Topics

Laminar and Non-Newtonian Corrections Panel

SSL Module Fluid Properties Group

HGL, EGL and head loss results may not be meaningful for variable density systems

Junction X has a density change across it. If this is due to a moving interface...

Related Examples

Related Blogs

Let the Heat Flow: Modeling Heat Transfer in Pipes in AFT Fathom and AFT Arrow