Cost Definitions

Depending on the contents of the associated Engineering Library there are tabs for Pipe Materials, Junctions, and Pipe Fittings & Losses. Each of these tabs serves the same purpose in slightly different ways - allowing the definition of costs for a certain component.

First, select a component of a certain type or size in the upper-left of the window. Then, click on the New Cost button. A new cost item is created in the table below as a new column. Some cells are displayed in black, which means that are not relevant to the type of entry selected.

Costs can be:

-

Material (NR)

-

Installation (NR)

-

Maintenance (R)

where the (NR) and (R) indicate Non-Recurring and Recurring. Non-Recurring Costs are calculated as a sum total for the model, whereas Recurring costs require a time period and a total system life, as defined in the Cost Settings panel of Analysis Setup.

These costs are on either a per-item, per-length, or time basis. The costs can further be adjusted with Scale Tables.

Pipe Materials Costs

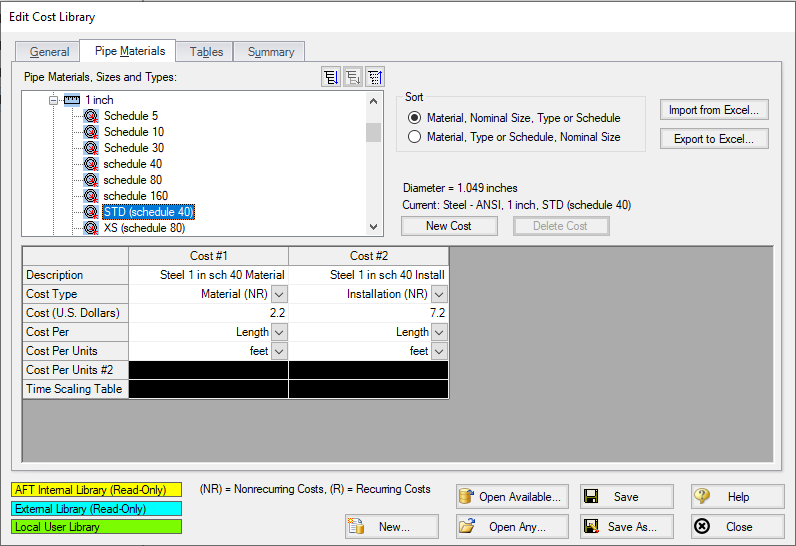

Figure 1: Cost Definitions for a Pipe Material

The Pipe Materials tab shows all the pipes in the engineering cost library. Costs can be entered at several levels. You can enter costs at the material level, the nominal size level, and finally at the type (e.g. schedule) level. Costs entered at the material apply to all pipes nominal sizes and types in that material type. Costs entered at the nominal size level apply to all schedules within that nominal size. Costs entered at the type level apply only to that type.

To make this process easier, values can be imported or exported to excel. The easiest way to import cost data from Excel is to first export the desired pipe Sizes and Types. Only the currently selected Sizes and Types will be exported (if the Pipe Material is selected, all will be exported) with any currently defined cost information included.

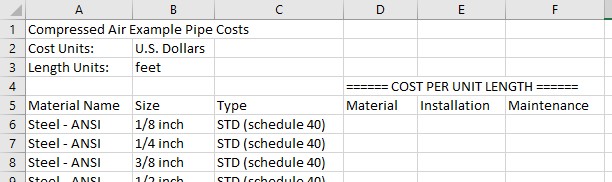

Figure 2: Excel Sheet for Importing Cost Definitions

The empty columns for cost per unit length can be filled in where cost data is required - it is not necessary to supply data for every cost, or for every Size/Type. After saving this sheet, the data can be imported directly with "Import from Excel."

Recurring costs for Pipe Materials can be modified with a Time Scaling Table.

Junctions Costs

Costs can be entered for all junction types.

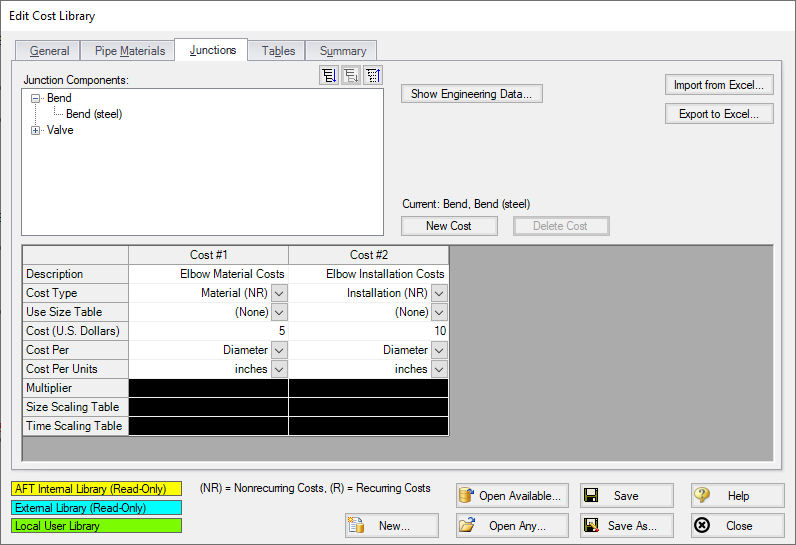

Figure 3: Cost Definitions for a Bend

Above is an example of entering cost data for a bend junction. Junction costs can also be entered at a higher level. For example, you can apply a cost to all Smooth Flanged Elbows.

Junction costs can be scaled with a Table of Multipliers, Table of Costs, or a Time Scaling Table.

The behavior of certain junctions varies slightly:

-

Compressors/Fans - Cost can be entered per item (compressor) or per Power. This will allow an approximate scaling for the size of the compressor on a more reasonable basis than diameter.

-

Control Valves - Costs can be entered per item or diameter. With a Scale Table, costs can be scaled based on Cv.

-

Other Junctions - Costs can be entered per item or diameter. Scaling tables can also be used on a diameter basis.

Pipe Fittings & Losses Costs

Cost specification functions the same as non-compressor junctions, with the exception that fitting & loss costs can be associated with a particular pipe material and size. Since the pipe fitting & loss engineering library is included only in the AFT Arrow internal library, cost data for pipe fittings & losses can only be entered when the cost library is associated with the internal engineering library – unless you add your own custom fittings & losses to an engineering library. Then cost libraries can be associated with that library as well.

Related Topics

Related Examples