Output Parameters

A variety of parameters are available to display in the Output window depending on the junctions and loss models used in the model.

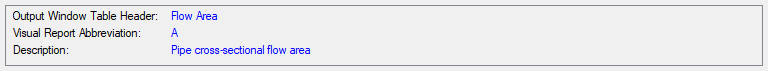

A description of each parameter may be seen by double-clicking the header in the Output Window table, and is also displayed below the Output Parameters table when that parameter is selected in the Output Control window (Figure 1).

Additional information can be found below for some of the output parameters.

Figure 1: A description is provided at the bottom of Output Control for the selected parameter

Cv Est./Kv Est.

The estimated Cv is only displayed when the valve does not have a defined Cv loss value. The estimated Cv/Kv loss coefficient is estimated using the sizing equations from the ANSI/ISA-75.01.01-2012ANSI/ISA Standard 75.01.01-2012, Industrial-Process Control Valves - Part 2-1: Flow Capacity - Sizing equations for fluid flow under installed conditions, 2012, published by International Society of Automation, Research Triangle Park, North Carolina, USA standard, as are discussed in the Valve Kv and Cv Flow Coefficients topic.

Equivalent Orifice Area/Diameter

The Equivalent Orifice Area and Equivalent Orifice Diameter is calculated using the sharp-edged orifice loss model with an assumed discharge coefficient of 0.6. The equivalent orifice calculations assume that flow is choked at the orifice.

Mass Flow Rate Net At Junction

Displays the total mass flow rate exiting the system through the junction, which is useful to display the flow exiting through junctions such as a spray discharge. In other words, the Mass Flow Rate Net At Junction is equal to the flow rate into the junction from the pipes minus the flow rate out of the junction into the pipes.

Mass Flow Rate Through Junction

Displays the total mass flow rate through the junction for junctions connected to only two pipes. If the junction is connected to more than two pipes this parameter will be displayed as N/A. When more than two pipes are connected the user should refer to the output for the pipes connected to the junction in order to view the flow rate through the pipes. The user can add the "Mass Flow Rate Net At Junction" to view flow exiting the system rather than flowing out of the junction into a pipe.