Use the Model Data Window

Besides its usefulness for documentation purposes, the Model Data window is a powerful tool for finding input errors in your model.

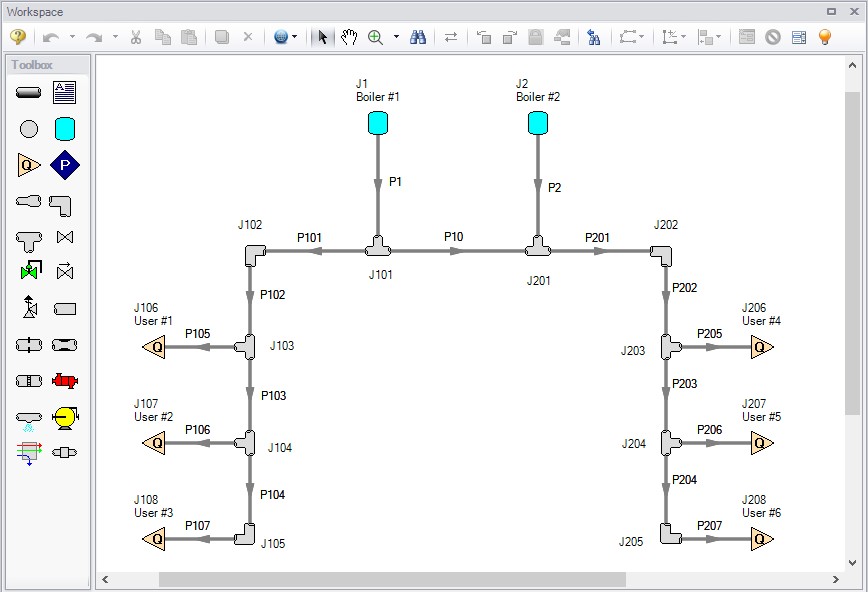

Look at the model in Figure 1. If you suspected an input error in one of the pipes, the task of looking for the error in each individual pipe input window would be tedious.

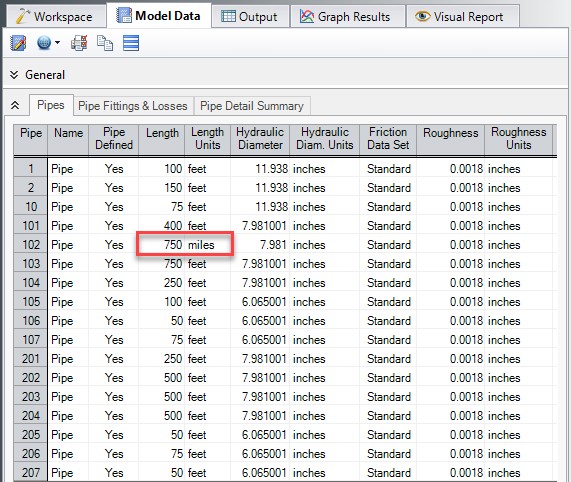

Now look at the Model Data window for the pipes in Figure 2. Here it is much easier to scan down columns of data looking for input errors. In this case, one of the pipe lengths was accidentally entered in miles rather than feet.

Figure 1: Workspace layout of a pipe system with an input error in one of the pipes (error not shown)

Figure 2: Model Data window display for the model in Figure 1. From this perspective it is much easier to see that one of the pipes (P102) has length data entered in miles rather than feet. This is not automatically an input error, as AFT Arrow accepts pipe input with mixed engineering units. However, the user often intends to use consistent units, so this probably is an error.

Related Topics

Transfer Results to Initial Guesses

Poor Compressor/Fan Curve Fits

Troubleshooting Resistance Curves

Use the Output Window Sort Feature

Lower the Flow Rate Relaxation

Make Initial Flow Rate Guesses for Pipes

Break a Large Model Into Submodels

Try a Different Fluid, Equation of State or Accuracy Option

Using Lumped Adiabatic as a Starting Point

These results do not represent a converged solution. Use only for error resolution purposes

Related Blogs