Sizing Pipes And Compressors Concurrently

The cost of a compressed gas piping system clearly depends on both the cost of the pipes, and the compressor. It is tempting to select compressors and pipes in stages, but this is unlikely to produce the lowest cost solution. Selecting a smaller compressor may not appear to be viable, but changing the pipe sizes may make it viable. Like sizing pipes alone, overall costs can often be decreased by increasing the cost of one or a few components. Attempting to find the lowest cost option manually quickly becomes impractical even with a small number of variables.

Optimal Pumping System Operating Point (OPSOP)

A compressor's BEP is considered the ideal place to run a compressor as the efficiency is highest, and thus cost is lowest. Similarly, any piping system will have a lowest cost design.

Whether a compressor is running at BEP, however, depends on the piping system, and the lowest cost piping system depends on the compressors it contains. What may be the lowest cost piping system for a given compressor, may not me the lowest possible cost option. It is possible that a cheaper compressor could be selected with the correct piping adjustments while still maintaining all Design Requirements.

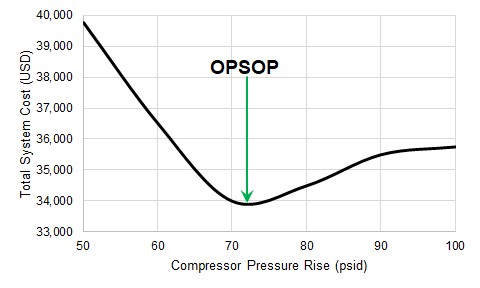

The point at which no adjustments to compressor or system will result in lower cost is known as the Optimal Piping System Operating Point (OPSOP). One way to determine this point is to exhaustively size the system for different potential sizes of compressors. This is inefficient, but can be used to construct a visual representation of the OPSOP as shown below.

Figure 1: The OPSOP of a given system. Note that every point is an ideal sizing solution for the given compressor size.

If the sizing process is approached in stages, rather than concurrently, it is easy to get a result that says, for example, a 60 psid pressure rise compressor is required. The best case system for the 60 psid pressure rise compressor has a minimum cost of about $36,500. However, allowing the compressor to change as well can result in a system more than 7% cheaper.

Process Outline

-

Find the Approximate Compressor Size

-

Model the compressor with the Compressor Sizing option, fixing the flow to the desired amount. AFT Arrow will determine the required pressure rise.

-

Include an estimate of Nominal Efficiency.

-

-

Add the compressor to an Engineering Library.

-

Attach a Cost Library to the Engineering Library if one does not already exist.

-

Create a Power vs. Cost Scale Table for the compressor with estimated cost values.

-

-

Select the appropriate options in the Sizing Window.

-

The cost for the compressor will only be included in the Objective if it is specified to be included in Size/Cost Assignments.

-

If there are several compressors that will ultimately be of the same type, they should be placed into a Maximum Cost Group.

-

-

Run ANS.

-

Investigate the resulting compressor size.

-

Update the Nominal Efficiency based on the result. Also update the cost information if necessary. If the compressor accounts for a large portion of the overall cost, accurate values here are more important.

-

Repeat the process as necessary, until reasonable estimates for cost at the resulting operating point are obtained.

-

-

-

Compare Candidate compressors

-

Locate accurate cost information and compressor curves for the candidates.

-

Incorporate these values into Engineering and Cost Libraries.

-

-

Compare the sizing results for each candidate compressor.

-

Estimating Compressor Costs

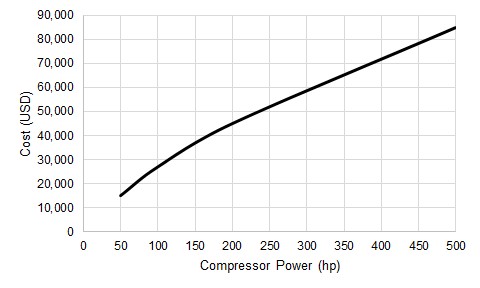

Without knowing specifically what type or size of compressor is going to be included in the system, the compressor behavior must be approximated. The behavior is approximated with the Compressor Sizing option, indicated with a design flow. We also need to approximate cost. Because energy cost is often the largest component of a compressor's overall cost, and this cost is directly related to the compressor's power, it makes sense to correlate other compressor costs to power as well.

Figure 2 - Total Initial Costs for a series of compressors

Keep in mind that such a comparison is only valid for the selected range of compressors. Different designs of compressors, or compressors from different manufacturers may follow different relationships. One manufacturer may offer cheaper low-power compressors, while their competitor offers cheaper high-power compressors. This cost information is represented in ANS as a Power vs Cost Scale Table. This requires the creation of a Cost Library including the compressor as a Custom Component.

Because we do not know what specific compressor is going to be used, we also do not know exactly how much it will cost to run or maintain it.

As part of our sizing process, we must assume that the compressor runs at some Nominal Efficiency. AFT Arrow will calculate the fluid power required at any given flow and head rise. However, a compressor or motor is not perfectly efficient and will therefore require more power than the fluid power. This affects the compressor selection, and therefore cost, so it is important to include an estimate on efficiency.

Note: It may seem that including a nominal efficiency is not important, as selecting a certain compressor size will minimize the initial compressor cost regardless of this value. However, this does not consider the cost of power over a long period, which is often a driving factor in sizing. Also, it is important to get the relative cost of the compressor correct as this can affect the best sizing. The nominal efficiency will require more power and hence a more expensive compressor - as this is included in the Objective, it is important to account for.

If maintenance costs are expected to be significant, it is important to include an estimate of these costs. Again, this could be accounted for with a Power vs Cost Scale Table.

The Approximate Sizing Solution

When the initial model is defined, the sizing configuration complete, and the compressors appropriately defined with approximate cost information, the automated sizing can take place.

ANS will size the pipes of the system to minimize cost while obeying Design Requirements. It will now include a power-based cost for the compressor. Without cost information on the compressor, ANS would tend to select small pipe sizes to reduce cost without any negative consequence. However, smaller pipe sizes have higher frictional loss, which requires greater pressure rise at the compressor, and hence higher cost. By including compressor cost information, the balance between compressor costs and piping costs can be found.

However, this is still an estimate because we are not modeling a real compressor. Fixing the flow and nominal efficiency are good design tools but it is important to represent a real compressor curve not only to account for real effects, but also to ensure that the desired compressor can actually be acquired.

If the compressor costs are a significant portion of the overall cost, the estimates made for cost and nominal efficiency should be refined and the system re-sized before proceeding.

Sizing with a Real Compressor

Now that there is a good idea of the size and cost of compressor we are looking for, we can select a real compressor we may want to use.

It will rarely be clear which compressor is the best choice. First, the exact operating point determined from the approximate solution is likely unavailable in a commercially available compressor. Second, different compressors have different costs - even if a compressor with the exactly correct specifications is available, it may be much more expensive than a compressor that is slightly mismatched. This cost difference could mean the cheaper compressor is better overall, despite not appearing to be the ideal choice.

The best course is to select several candidate compressors, and size the system independently with each candidate compressor. It is important that accurate compressor curves and cost information be included for each candidate, as this no longer meant to be an estimation. After testing each candidate compressor, the system with the lowest overall cost can be selected.

If the sizing results differ significantly in this stage this could indicate that the compressor is poorly matched, that there was an error in the process, or that the system is dominated by compressor costs and therefore very sensitive to the estimations.