Beginner: Pump Sizing for Sand Transfer System - SSL (English Units)

Beginner: Pump Sizing for Sand Transfer System - SSL (Metric Units)

Summary

This example demonstrates the fundamental concepts of the Settling Slurry (SSL) add-on module by way of example. The example shows how SSL can be used to size a slurry pump as part of a system design process.

The piping for a slurry system that moves sand is being designed. The system will pump 25% sand by volume from an open supply vessel with a liquid surface elevation of

Use the SSL module to size the pump.

Note: This example can only be run if you have a license for the SSL module.

Topics Covered

-

Entering solids data

-

Reviewing calculated slurry output

-

Creating slurry system curves

Required Knowledge

This example assumes the user has already worked through the Walk-Through Examples section, and has a level of knowledge consistent with the topics covered there. If this is not the case, please review the Walk-Through Examples, beginning with the Beginner: Three Reservoir Model example. You can also watch the AFT Fathom Quick Start Video Tutorial Series on the AFT website, as it covers the majority of the topics discussed in the Three-Reservoir Model example.

Model File

This example uses the following file, which is installed in the Examples folder as part of the AFT Fathom installation:

Step 1. Start AFT Fathom

From the Start Menu choose the AFT Fathom 12 folder and select AFT Fathom 12.

To ensure that your results are the same as those presented in this documentation, this example should be run using all default AFT Fathom settings, unless you are specifically instructed to do otherwise.

Step 2. Define the Modules Panel

Open Analysis Setup from the toolbar or from the Analysis menu. Navigate to the Modules panel. For this example, check the box next to Activate SSL and select Settling to enable the SSL module for use. The items in the Fluid Properties group will change to accommodate slurry definitions. Click OK to save the changes and exit Analysis Setup. Open the Analysis menu to see the new option called Slurry. From here you can quickly toggle between Disable mode (normal AFT Fathom) and Settling (SSL mode).

Step 3. Define the Fluid Properties Group

Open Analysis Setup from the toolbar or from the Analysis menu and input the following on the respective panels.

-

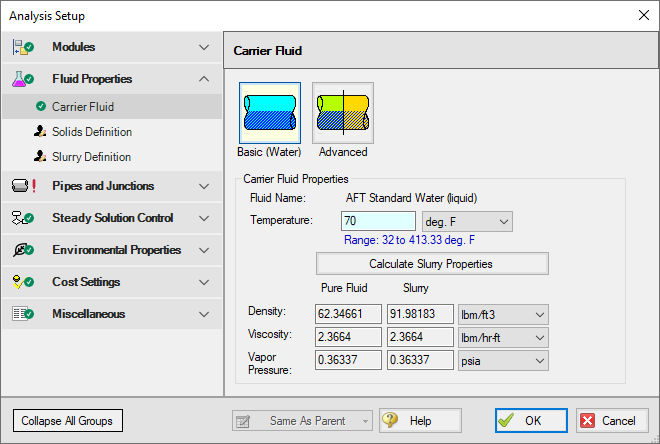

Carrier Fluid - Figure 1

-

Fluid Model = Basic (Water)

-

Temperature = 70 deg. F

-

-

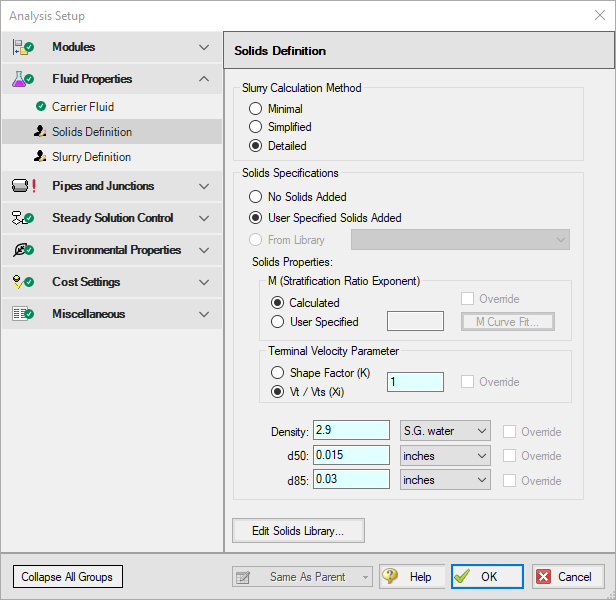

Solids Definition - Figure 2

-

Slurry Calculation Method = Detailed

-

Solids Specifications = User Specified Solids Added

-

M (Stratification Ratio Exponent) = Calculated

-

Terminal Velocity Parameter = Vt / Vts (Xi)

-

Value = 1

-

Density = 2.9 S.G. water

-

d50 = 0.015 inches

-

d85 = 0.03 inches

-

-

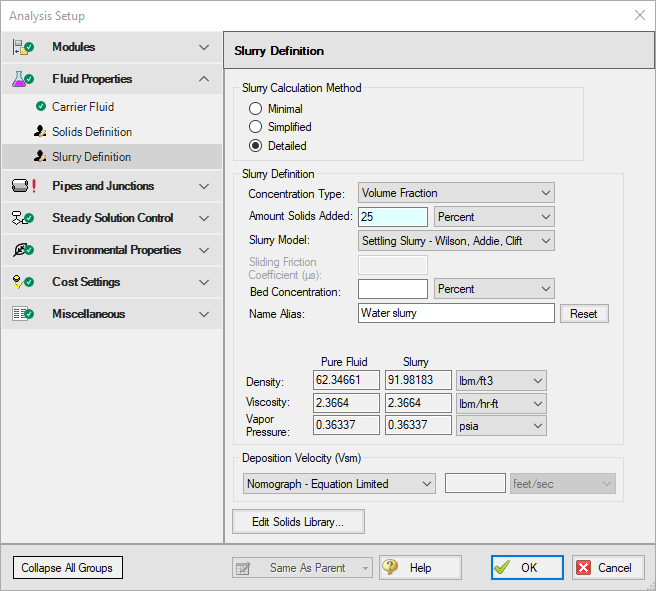

Slurry Definition - Figure 3

-

Slurry Calculation Method = Detailed (this selection will be the same as on the Solids Definition panel)

-

Concentration Type = Volume Fraction

-

Amount Solids Added = 25 Percent

-

Name Alias = Water slurry

-

Figure 2: Solids Definition panel in the Fluid Properties group in Analysis Setup with SSL activated

Figure 3: Slurry Definition panel in the Fluid Properties group in Analysis Setup with SSL activated

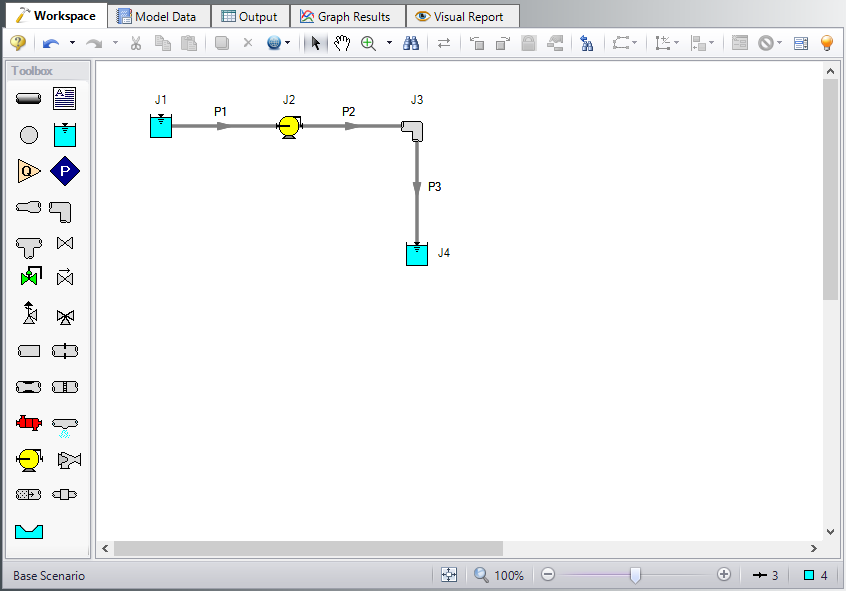

Step 4. Define the Pipes and Junctions Group

At this point, the first two groups are completed in Analysis Setup. The next undefined group is the Pipes and Junctions group. To define this group, the model needs to be assembled with all pipes and junctions fully defined. Click OK to save and exit Analysis Setup then assemble the model on the workspace as shown in the figure below.

Enter the following pipe and junction properties.

Pipe Properties

-

All Pipes

-

Pipe Material = Steel - ANSI

-

Pipe Geometry = Cylindrical Pipe

-

Size = 12 inch

-

Type = STD

-

Friction Model Data Set = Standard

-

Length =

| Pipe | Length (feet) |

|---|---|

| 1 | 20 |

| 2 | 500 |

| 3 | 50 |

Junction Properties

-

J1 Reservoir

-

Name = Supply Tank

-

Liquid Surface Elevation = 5 feet

-

Liquid Surface Pressure = 10 psig

-

Pipe Depth = 5 feet

-

-

J2 Pump

-

Inlet Elevation = 0 feet

-

Pump Model tab

-

Pump Model = Centrifugal (Rotodynamic)

-

Analysis Type = Sizing

-

Parameter = Mass Flow Rate

-

Fixed Flow Rate = 1400 ton/hr Solids

-

-

Slurry De-Rating tab

-

De-Rating Method = ANSI/HI Standard 12.1-12.6-2016

-

Percent Fines = 0 %

-

Head De-Rating Data = Specify Impeller Size Directly

-

Impeller Size = 8 inches

-

-

-

J3 Elbow

-

Inlet Elevation = 0 feet

-

Type = Standard Elbow (knee, threaded)

-

Angle = 90 Degrees

-

-

J4 Reservoir

-

Name = Receiving Tank

-

Liquid Surface Elevation = 10 feet

-

Liquid Surface Pressure = 30 psig

-

Pipe Depth = 10 feet

-

ØTurn on Show Object Status from the View menu to verify if all data is entered. If so, the Pipes and Junctions group in Analysis Setup will have a check mark. If not, the uncompleted pipes or junctions will have their number shown in red. If this happens, go back to the uncompleted pipes or junctions and enter the missing data.

Step 5. Run the Model

Click Run Model on the toolbar or from the Analysis menu. This will open the Solution Progress window. This window allows you to watch as the AFT Fathom solver converges on the answer. This model runs very quickly. Now view the results by clicking the Output button at the bottom of the Solution Progress window.

Step 6. Examine the Output

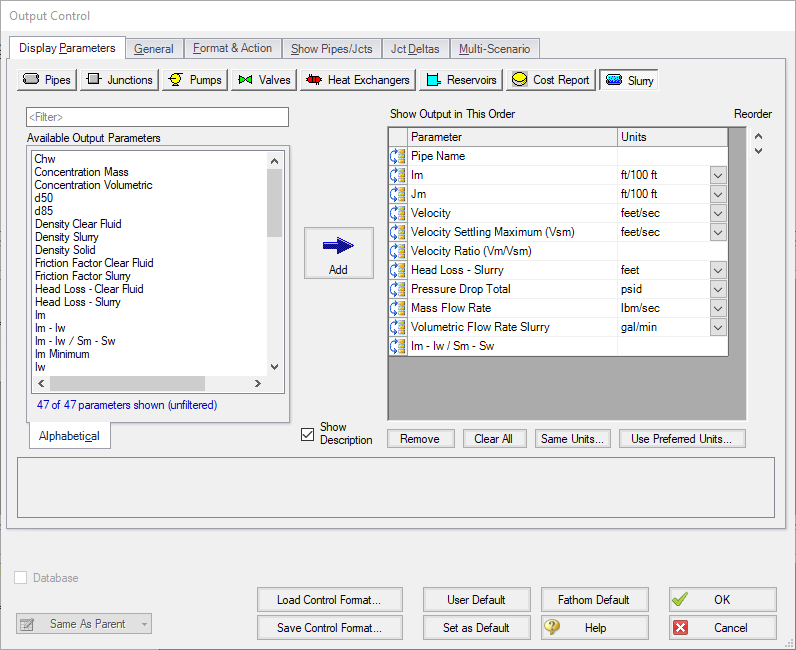

Open the Output Control window by selecting Output Control from the Output toolbar or Tools menu.

On the Display Parameters tab, click the Pumps button, and add the De-rating Head Correction factor (CH) to the Pump Summary output.

The Output Control window can also be used to configure the slurry output data, as is shown in Figure 5. Click OK when you are finished.

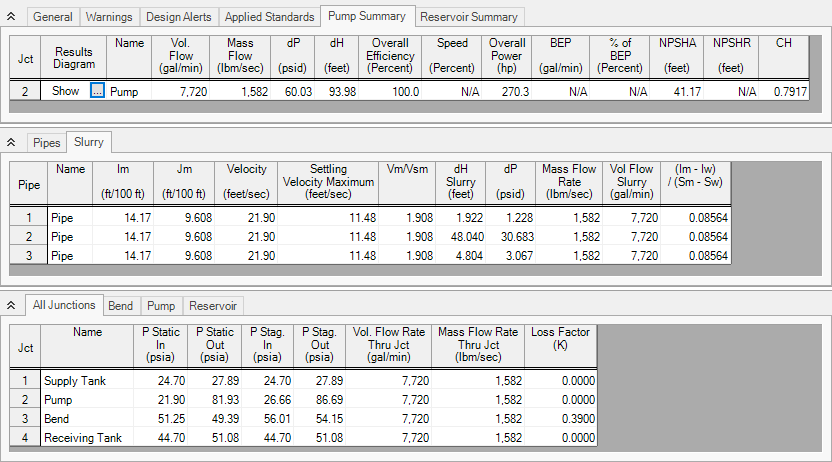

The Slurry tab in the pipes section shows the slurry results, as shown in Figure 6. Here one can see that the velocity is

Also shown in Figure 6 is the Pump Summary in the General Section. There the required pump head is shown as

Figure 6: The Output window shows the Slurry results table in the center Pipes section and the pump de-rating in the Pump Summary in the upper General section

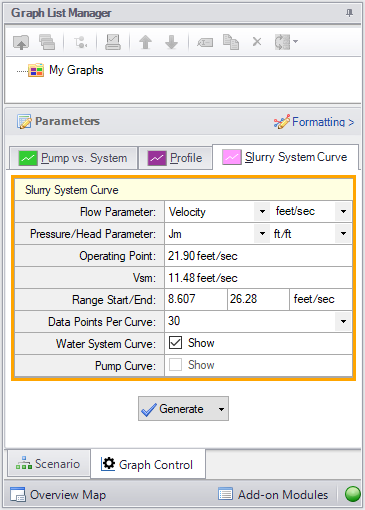

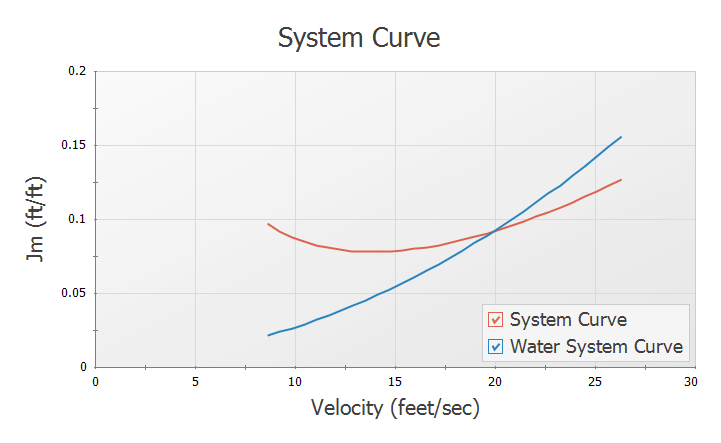

Also of interest is the system curve. Select the Graph Results window tab then in the Graph Control tab in the Quick Access Panel select the Slurry System Curve tab. See Figure 7.

By default the parameter to graph is Jm vs. Velocity. Select the units of Jm as

A slurry of sand and water flowing through