Feasible and Infeasible Designs

If a system has Design Requirements, there will be designs unable to meet the requirements. These designs are termed Infeasible - configurations that violate Design Requirements. Likewise, configurations that meet all Design Requirements are Feasible.

Feasibility can be determined without any knowledge of the Objective. While it is not directly related to the Objective, feasibility can heavily influence the sizing process. It is typical that the ideal solutions are infeasible because they do not meet the Design Requirements. Instead, the best solution is where the Objective is met in the feasible space. Not all Design Requirements will impact the sizing in the same way.

It is important not to confuse infeasible design with impossible design. A potential design being infeasible does not mean that the system could not be built as specified. In fact, it is possible that the system could run quite well. It only means that a specified Design Requirement has been violated.

Conceptual Example

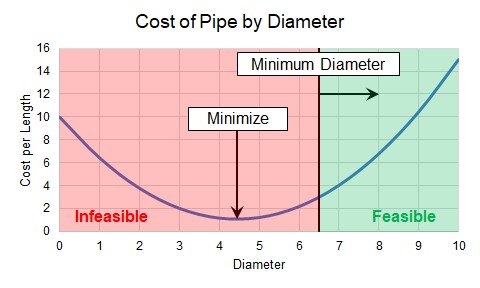

We previously added a Design Requirement to our pipe, which makes certain designs Infeasible (Figure 1). The minimum flow rate Design Requirement requires a minimum diameter.

Figure 1: Certain diameters are infeasible when a Design Requirement is added

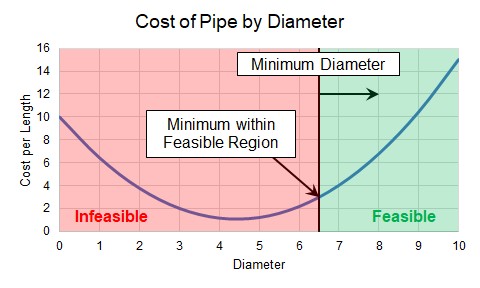

Clearly, our best case minimum cost is now in the Infeasible region. This would still be the cheapest pipe to select, but would limit flow too much. Instead, we need to find the minimum cost within the feasible region (Figure 2).

Figure 2: Minimum Feasible Cost

Because our cost only increases with diameters larger than our minimum, the best case cost is now the minimum diameter possible due to the flow requirement. This means that the Design Requirement is Active.