Initial Costs and Recurring Costs

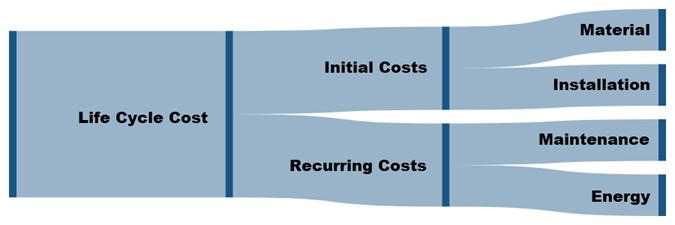

Systems can be sized for a variety of costs. Most notably, there are Initial Costs and Recurring Costs. The sum of the Initial Costs and Recurring Costs over the expected system lifetime is known as Life Cycle Cost.

Initial Costs include any one-time cost that is required to get the system in question operational. Most often, this is a combination of Material and Installation costs.

Recurring Costs include any cost that accrues over time (Figure 1). This could be fixed costs at regular intervals, such as the cost of routine Maintenance. It can also be the potentially variable cost of energy to run pumps.

Note: Costs must be defined in Cost Libraries, which are available as part of the base Application.

Figure 1: Components of Life Cycle Cost

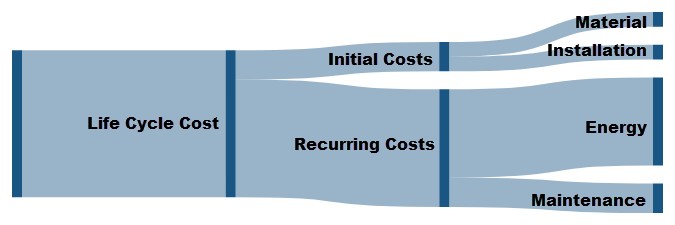

Keep in mind when considering what costs to include what your most significant cost is likely to be. Systems are often designed to run for many years. This generally means that the total cost of running the system ends up as much more than the cost of building it. Fully defining the sizing input for minimizing Life Cycle Cost is more difficult, but often worthwhile. The inclusion of cost components is defined in the Sizing Objective panel.

Figure 2: Potential distribution of costs for a long System Life