Design Requirement Panel

Design Requirements are of critical importance in a sizing process. Without any Design Requirements, the system will be sized based on cost alone. This will tend to reduce pipe diameters to the minimum size allowed by the Candidate Set. In turn, the fluid behavior of the system may become physically untenable - for example, with extremely high fluid velocities.

Additionally, the very requirements of the system may not be met - certain outflows may require a given pressure and flow and lowering the pipe size too much may mean these needs cannot be met.

Design Requirements ensure that the selected pipe sizes are the minimum cost considering these limitations - the minimum Feasible cost.

Define Design Requirements

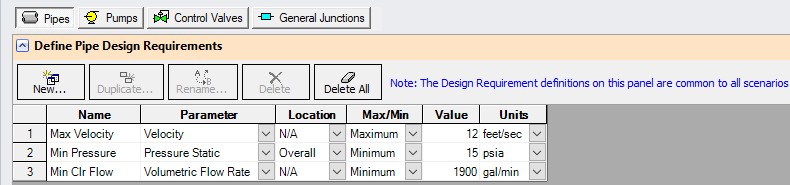

Pipes and Junctions can both have Design Requirements applied to them (Figure 1). In both cases, individual Design Requirements are defined with a Name, Parameter, Location, and limiting Value.

Figure 1: Defined Design Requirements in the Define Pipe Design Requirements

Note: The Design Requirements defined here are common to all scenarios. They can be applied or not applied in certain scenarios as needed.

Assign Design Requirements

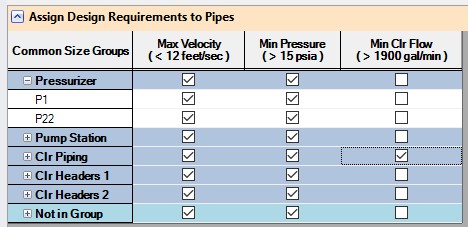

Created Design Requirements can be applied to any number of applicable objects, and a single object can have any number of Design Requirements applied to it. Common Size Groups are indicated here, and a Design Requirement can be applied to an entire group with ease (Figure 2). If this is not desired, the group can be expanded and individual selections can be made.

Figure 2: Created Design Requirements can be assigned to multiple objects