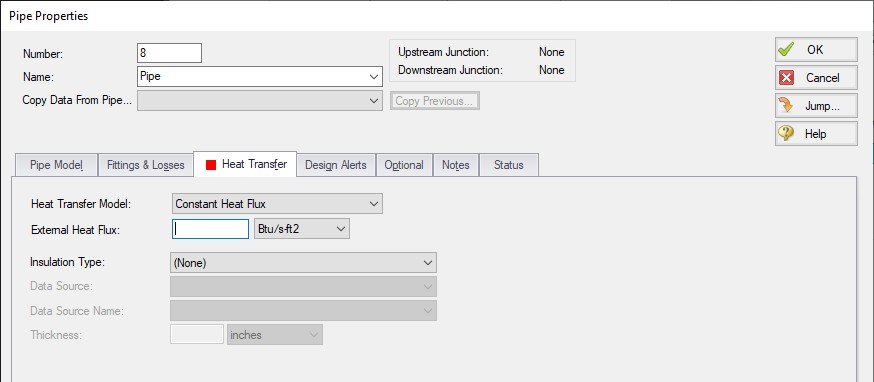

Constant Heat Transfer

There are 4 thermal models for pipes in AFT Fathom which fix the thermal behavior of the pipe to some constant value

-

Adiabatic (Perfectly Insulated) - The heat transfer between the pipe and the environment is fixed to zero. The entire length of the pipe will have a stagnation enthalpy equal to that of the upstream junction. The actual fluid temperature depends on the system.

-

Isothermal - The fluid temperature is set to a specified value. Heat transfer is still modeled in this case - instead of varying the fluid temperature, the heat rate into or out of the pipe is found that satisfies the isothermal constraint.

-

Constant Heat Flux - A constant heat flux (heat rate per area) is applied to the pipe. Positive values indicate heat entering the pipe. Flux is often a more readily available and flexible value for some conditions, such as radiation heat transfer. For this model, the heat flux is applied to the area defined by the ID of the pipe. To model a heat flux underneath insulation, use the Convective Heat Transfer with Heat Tracing model.

-

Constant Heat Rate - It may also be known that a certain pipe transfers (or needs to transfer) a specific heat rate, regardless of the size of the pipe. This model allows the specification of a constant energy per time into or out of the pipe.

The above models follow a common format on the Pipe's Heat Transfer tab, as shown below. There is only one required value input unless insulation is added. One layer of insulation (external or internal) can be added, with conductivity values from a library or User Specified in this window.

Note: The Heat Transfer tab will not be present unless heat transfer has been enabled from the Heat Transfer/Variable Fluids panel of the Fluid Properties group in the Analysis Setup window.

Figure 1: Constant Heat Flux

Related Blogs

Let the Heat Flow: Modeling Heat Transfer in Pipes in AFT Fathom and AFT Arrow