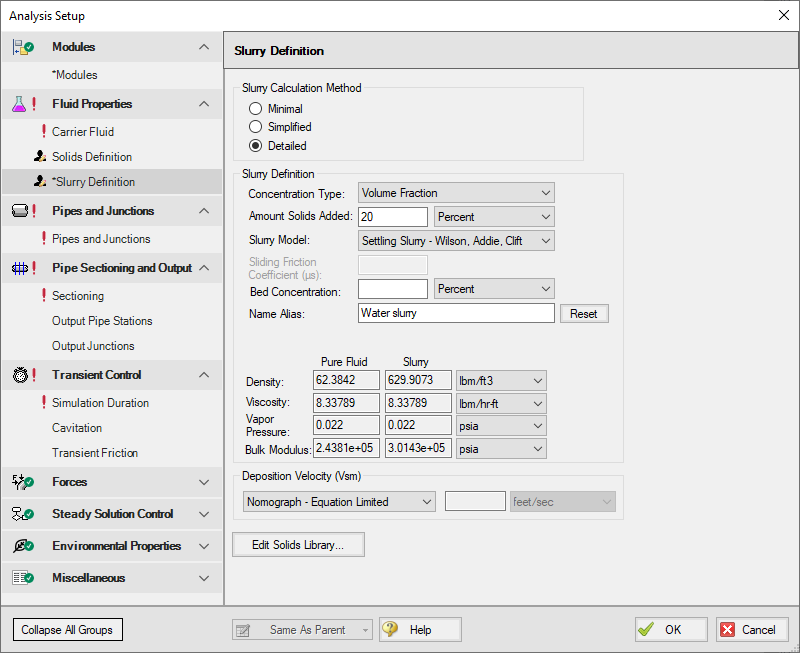

Slurry Definition Panel

The Slurry Definition Panel allows input of solids concentration relative to the carrier fluid and estimation of bulk slurry properties, as shown in Figure 1.

Override options are provided for a number of parameters that allows users to modify data pulled from libraries should modeling requirements need this.

Figure 1: Slurry Definition Panel when Detailed Slurry Calculation Method and User Specified Solids Added are selected

Slurry Calculation Method

There are three calculation methods available to model slurries. Each method requires different amounts of input data and uses different calculations. These calculations are described in the Slurry Calculation Methods section.

-

Minimal Method - Used in the preliminarly design phase where only rough data is available. The solids density, sliding friction coefficient, and solids concentration are the only parameters needed. However, due to the minimal data used, the calculations should only be used for early stage approximations. This is a conservative method that assumes a fully-stratified sliding bed.

-

Simplified Method - Additional information is required and gives a better solution. This method requires the solids density, d50 particle size, a user-specified M exponent, and the solids concentration. This method assumes heterogeneous flow withing suspended particles. The Simplified Method is a more accurate model than the Minimal method because it accounts for more slurry definition.

-

Detailed Method - The default method, and the method which provides the most rigourous solution methodology. The solids density, d50 particle size, terminal velocity parameter, and the solids concentration are required. Additionally, if the M exponent is calculated, the d85 particle size is required. As with the Simplified Method, this method also assumes heterogenous flow with suspended particles.

Slurry Definition

The Concentration Type is used to specify a value in the Amount Solids Added field. The available options for Concentration Type are:

-

Grams per Liter of Mixture

-

Volume Fraction

-

Mass Fraction

-

Solids Ratio (M-solids/M-liquid)

There are two Slurry Model options to choose from. These options determine the calculations used in the solver.

-

Newtonian - Functionally disables most of the SSL module calculations and preserves only the viscosity properties of the fluid in the model

-

Settling Slurry - Wilson, Addie, Clift - Default option, applies slurry calculations from Wilson

The Sliding Friction Coefficient (μs) is the coefficient of mechanical sliding friction between the granular mass and the boundary - where the boundary is the where the motion takes place between the mass and a rigid boundary, i.e. the pipe wall. As the Sliding Friction Coefficient increases, so does the friction and thereby the pressure drop through the pipe. This field is only available when the Minimal Slurry Calculation Method is selected at the top of the panel.

The Bed Concentration (Cvb) is an optional parameter and is only used to determine the actual settling velocity (Vs) shown in the output. These calculations are described in Wilson (1986)Wilson, K.C., “Effect of Solids Concentration on Deposit Velocity”, Journal of Pipelines, 5, 1986, pp. 251-257. and are functions of the pipe diameter, particle size (d50), particle density and relative concentration. If no value is entered for this parameter then a default of 0.60 is used. The maximum value of these settling velocities (Vs) is denoted as Vsm and is the usual parameter of interest in designing a system to avoid operating with a stationary bed. This field is only available when the Simplified and Detailed Slurry Calculation Methods are specified at the top of the panel.

Deposition Velocity (Vsm)

The Deposition Velocity (Vsm) can be determined using one of the options below. This is useful when the calculation method yields a slightly different value than, say, test results.

-

Nomograph - Equation Limited - This option is the default and uses the nomograph from Wilson (1986)Wilson, K.C., “Effect of Solids Concentration on Deposit Velocity”, Journal of Pipelines, 5, 1986, pp. 251-257. page 111. The nomograph is noted to be conservatively high by Wilson, so an equation that calculates the max Vsm is used to limit the value of Vsm.

The results calculated from the nomograph will be checked against Equation 5.11 from Wilson (1986) as is shown below. If the value from the nomograph exceeds Vsm,max calculated from Equation 5.11, then the Vsm,max from Equation 5.11 will be used instead.

Note: If the Vsm is calculated as a negative value using Equation 5.11 from Wilson then the Vsm will be displayed as 0 in the Output. If the Vsm is shown as 0, the inputs for the fluid and solid should be verified, and the user should consider calculating the Vsm using a separate method.

-

Equation Only - This option will cause the Vsm to be calculated solely using Equation 5.11.

-

User Specified - This option allows the user to directly specify Vsm.

As Wilson describes there are times where operating at a velocity lower than Vsm is economically attractive and is without a stationary bed. These cases include a system where the solid concentration at the desired operating point is very different than that at the Vsm conditions. Wilson points out that this is rarely the case, and so the use of Vs instead of Vsm should be done with caution.