Troubleshooting Artificial Transients

It is relatively clear how an Artificial Transient is detected, but diagnosing its source and fixing the problem can be much more complicated. Often, the best course of action will be to send the model to AFT Support. The tools provided by AFT Impulse can help point you in the right direction.

First, take a look at the Output. Even though the transient simulation is halted when an Artificial Transient is detected, the Output will still provide valuable information.

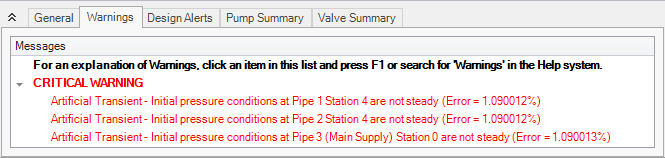

Figure 1: Artificial Transient Warnings

The Warnings tab will give information on the Artificial Transient(s). In Figure 1, we can see that the pressure is inconsistent at the entrance to pipe P1, P2, and P3. These 3 pipes connect to a branch junction. A pressure change of 1% will not cause excessively large non-real pressure transients to move through the system, but it may be enough to negatively impact the real results in the system. With this information alone, it may be possible to determine and solve the issue.

Second, if the location alone does not provide enough information, observe the behavior of the Artificial Transient. This will require allowing the transient simulation to proceed, by disabling the Stop Run option on the Artificial Transient Detection panel. To properly understand the Artificial Transient, it is critical that all other user-defined transients in the model are disabled. This can be most easily accomplished with a Transient Special Condition.

Note: An Artificial Transient is an affect strictly related to the beginning of the simulation. When troubleshooting, it is not necessary or advised to run a long simulation. Shorten the Simulation Duration as much as possible to make running the model quick. In many cases only a handful of time steps are needed.

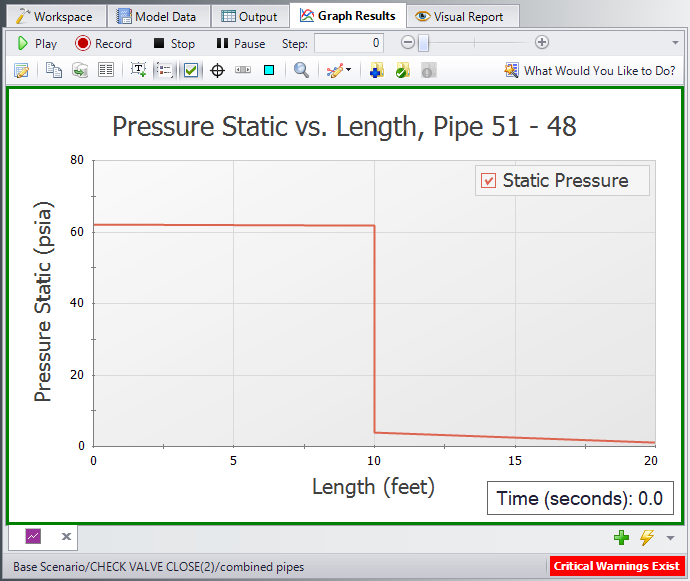

The most powerful Output tool for analysis of an Artificial Transient is the Animation of a Profile Graph. By animating the behavior it can be made clear where the event originates, as well as what kind of impact it has on the system. Again, user transients should be disabled which means the simulation should remain at a constant steady-state throughout the transient simulation.

Figure 2: A profile graph showing time step zero. This represents the initial steady-state solution.

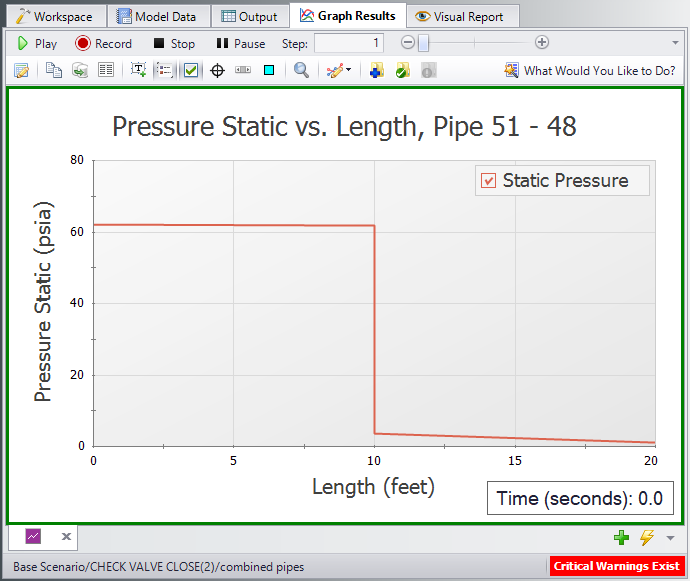

Advancing the animation just one time step shows a small change in the pressure profile:

Figure 3: The same profile graph showing the first time step. There is a dramatic change in pressure at J2, as reflected by the Warnings.

By allowing the animation to proceed, an assessment of the impact the Artificial Transient has on the system can be made. In this case, the effect is likely relatively small. However, in many cases the problem may not be small enough to be considered negligible. This depends heavily on the nature of the problem and the system, making general guidelines difficult to develop.

In this case, it's difficult to say definitively if this artificial transient needs to be addressed or not. However, it's always a good idea to attempt to resolve the issue and ensure that your transient analysis is not showing non-real results.

Third, the root of the Artificial Transient must be determined if it is not acceptable. This is often the most difficult step as there is no one potential cause.

The best approach is to consider the results above as well as the assumptions made by AFT Impulse and the various junctions. In the case above, a pump junction is using a four-quadrant data set that is giving invalid data during the transient. Note that there is an additional Critical Warning in Figure 1 to this effect. While this warning is being generated 2 seconds into the simulation rather at the same time as the artificial transient, it can still give a hint to the problem.

In this case, a four-quadrant data set is being used that is not well-suited to the pump in the model. Adjusting the model to use a better-suited data set resolved both the Artificial Transient and the error later in the simulation.

Note: Do not forget to re-enable the detection of Artificial Transients!

Related Topics

Artificial Transient Detection Panel

Artificial Transient Initial pressure conditions at Pipe X Station Y are not steady Error Z

Related Blogs

Are you for real? Understanding and Troubleshooting Artificial Transients in AFT Impulse