Brecht & Heller Method (Pulp and Paper Stock)

The Brecht and Heller method is a system developed by Brecht and Heller at the University of Maine and formalized by the Technical Association of the Pulp and Paper Industry (TAPPI) and the

This method is considered more conservative than the Duffy method, meaning the Brecht and Heller method will predict larger pressure losses in a system, all else constant.

Fathom contains data on eight different stock fluid selections that can be used with the Brecht and Heller method. The constants used for each stock fluid are displayed in the General Results section of the output. Additionally, the pseudo-Reynolds Number (Ré) and Friction Factor terms can be displayed in the Pipe Output.

Brecht and Heller Method Interface

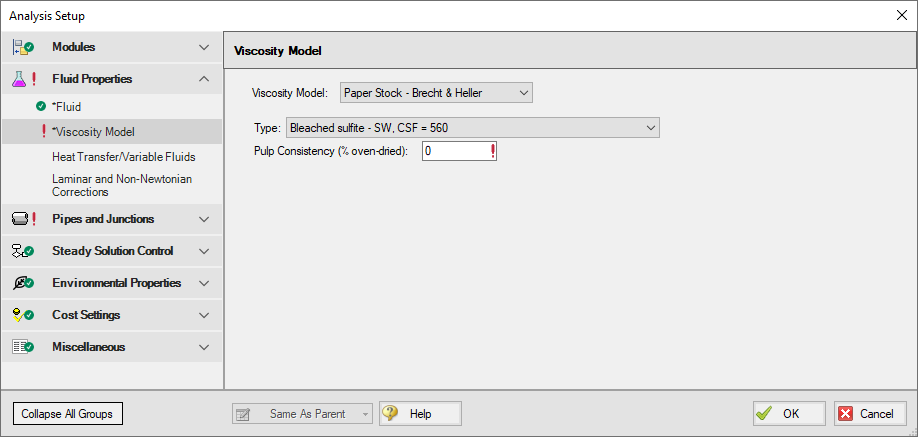

The Viscosity Model panel appears as shown below in Figure 1 when the Brecht & Heller method is selected.

Figure 1: Viscosity Model panel for the Brecht & Heller Method

Users must select a type of pulp model and define a pulp consistency. There eight pulp types to choose from:

-

Bleached sulfite - SW, CSF = 560

-

Pre-steamed groundwood - SW, CSF = 200

-

Reclaimed fiber

-

Soda - HW

-

Stone groundwood - SW, CSF = 70

-

Unbleached kraft - SW, CSF 730

-

Unbleached sulfite - SW, CSF = 640

-

Unbleached, unrefined sulfite SW

Theory and Correlations

AFT Fathom models frictional losses for the Brecht and Heller method using correlations taken from the Cameron Hydraulic HandbookIngersoll-Dresser Pumps, Cameron Hydraulic Data, Liberty Corner, NJ, 1995. , pg 3-88.

The pseudo-Reynolds number for the paper stock (Ré) is:

The pipe friction factor is:

The friction loss in feet along the pipe is:

Where:

-

D = inner diameter (feet)

-

L = pipe length (feet)

-

V= average velocity (feet/sec)

-

ρ= stock fluid density (lbm/ft3)

-

C = pulp consistency (% dryness)

-

K = friction factor constant, specific to pulp type (dimensionless)

Related Topics

Related Blogs

Non-Newtonian Fluids - How to Model the Soap, Silly-Putty, or Shampoo in Your Pipe Network