Pump Reliability Factors

Reliability factors from Bloch & Geitner (1994)Bloch, H. P., & Geitner, F. K. (1994). An Introduction to Machinery Reliability Assessment. Houston, Texas: Gulf Publishing Co. can be used to help assess the long-term reliability of pumps.

Setting up a Pump to Calculate Reliability

In order to calculate overall reliability, three pieces of pump data are needed:

-

Efficiency vs. Flow

-

Speed in RPM

-

Actual, maximum, and minimum impeller diameters

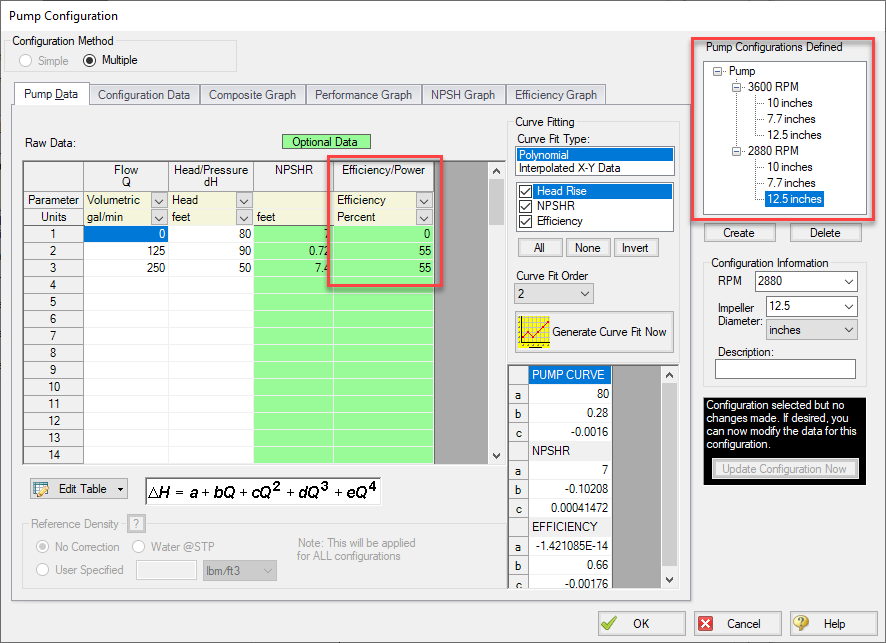

Figure 1 shows the Pump Configuration window which is opened from the Pump Specifications window. In the table at the left of Figure 1, you can see where efficiency data is entered. The best efficiency point (BEP) is computed based on this data. If you would rather enter the BEP directly you can do so on the second tab Configuration Data. The BEP data is used to compute the reliability factor based on BEP. AFT Fathom calls it Reliability Factor BEP or Reliability BEP.

Figure 1: Pump Configuration window opened from Pump Specifications window

At the top left of Figure 1 you can see options for Configuration Method. To calculate the reliability factors for speed and impeller you need to use the Multiple Configurations option as shown in Figure 1. When you choose this, the window expands to the right and you can see the areas at the right of Figure 1 where RPM and impeller size are specified. Each RPM and impeller size combination is referred to as a pump configuration. To make the reliability factor calculations work correctly here is the data that must be entered for the pump:

-

One configuration for the maximum impeller diameter must be entered

-

One configuration for the minimum impeller diameter must be entered

-

One configuration for the maximum speed in RPM must be entered

Using these three configurations, AFT Fathom searches all configurations for the pump and finds the maximum and minimum diameters to use for the impeller diameter based reliability factor which we call Reliability Factor Diameter. AFT Fathom also searches for the highest RPM value and assumes that as the design value. This value is then used for the Reliability Factor Speed calculation.

The Reliability Factor Total is simply the product of the BEP, Speed, and Diameter reliability factors.

Setting Pump Reliability in Output

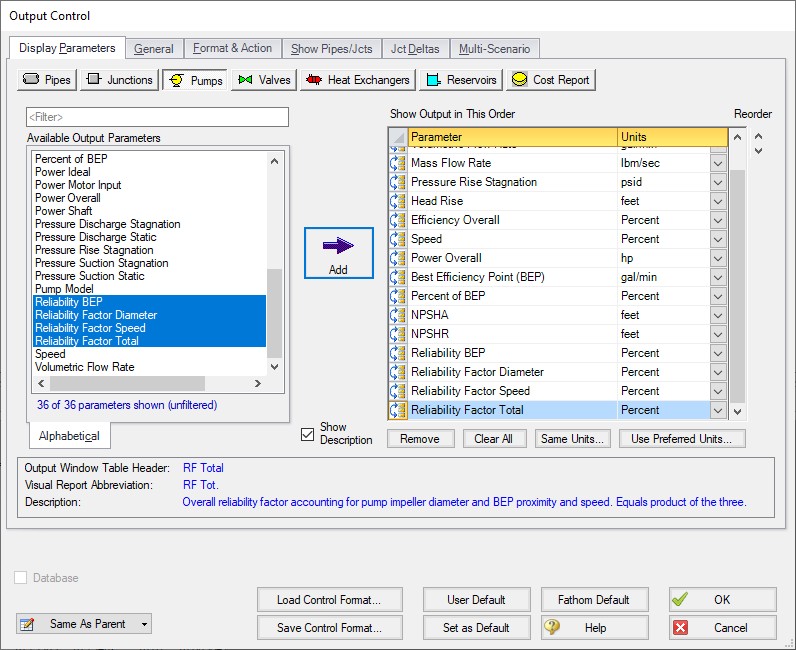

The reliability factors can be selected for viewing using the Output Control window. Choose Output Control from the Tools menu or click the Output Control button on the toolbar.

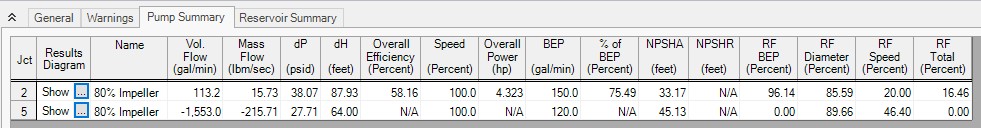

Choose the Pump button at the top of the Display Parameters tab, and from the list on the left select the reliability parameters you want to see in your output. Add them to the list on the right. When you run your model you will see the reliability factor output as in Figure 3.

Figure 2: Output Control Window with Reliability Factors added

Figure 3: Reliability Factors in the Pump Summary