Centrifugal Compressor

Analysis Type

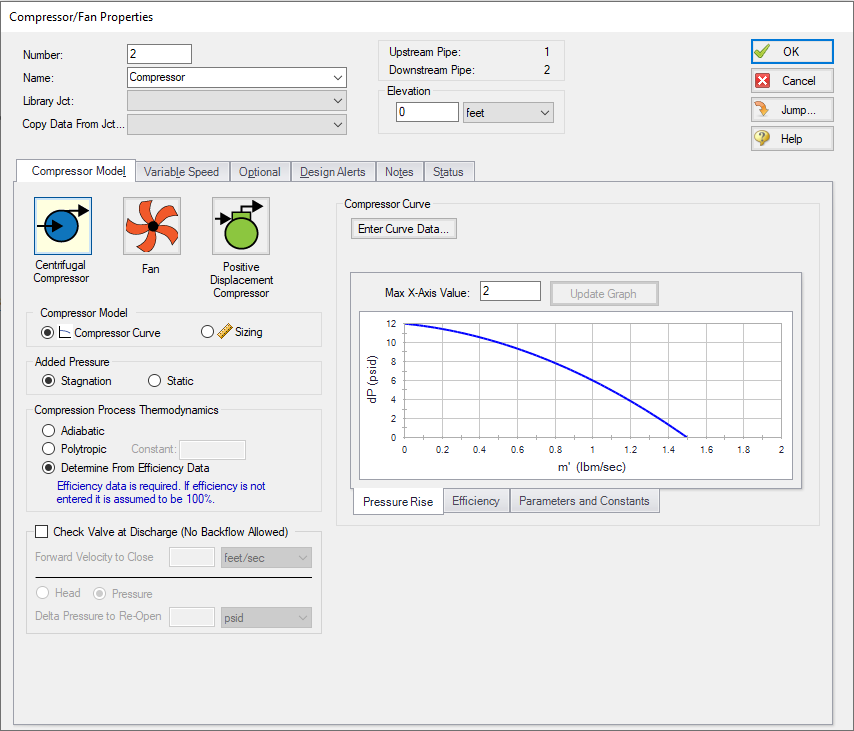

This topic pertains to the Centrifugal Compressor Curve Analysis option which represents the real behavior of a centrifugal compressor or fan. For Sizing Analyses, see Compressor/Fan Sizing.

Centrifugal Compressor Curve

The right hand side of the tab displays the defined curve(s) for the compressor.

To enter curves, click Enter Curve Data. Once this data has been defined, previews of the applied curves can be seen on the right hand side of the Compressor Model tab. Note that only one curve can be entered unless different configurations under the Multiple Configurations tab have been specified.

Note: AFT Arrow does not have a means to account for stall or surge lines for the compressor. Therefore, it is possible that Arrow will allow the compressor to operate at unrealistic conditions. It is advised that the user check the results to ensure that the compressor did not reach the surge or stall lines during the run, design alerts can be useful to assist with this.

Added Pressure

If the compressor curve is entered using pressure rise information as opposed to a head rise, the pressure rise will need to be specified as either a stagnation or static pressure. This specification is performed on the Compressor Model tab under the Centrifugal compressor specification. Note that mechanical energy rises are typically entered in Arrow as pressure rises instead of head rises because the usefulness of the head term in variable-density systems is diminished.

Compression Process Thermodynamics

Depending on the compression process, significant thermal effects can occur. Fans and blowers create a pressure rise that is typically so low that the temperature is not noticeably affected, which is why Arrow treats the Fan model as adiabatic, but the large pressure rise in compressors leads to significant temperature changes. This is also known as the heat of compression, and in Arrow, it can be accounted for in a compressor in multiple ways:

-

Adiabatic - The compressor is treated as adiabatic and 100% efficient. The compressor efficiency is treated as an isentropic efficiency, so 100% efficiency in this case means the compressor operation is isentropic. If the compression process is adiabatic, the temperature rise is given by the following isentropic relationship:

Note that these pressures and temperatures are static and not stagnation. Gamma (g) is the specific heat ratio.

-

Polytropic - If there is incidental heat loss to ambient, or if the compressor is actively cooled, the process will not be adiabatic. In this case the process is referred to as polytropic, and the temperature rise is given by the following:

where n is the polytropic exponent. If n is equal to γ, it is adiabatic. Typically, n is greater than γ for compressors.

-

Determine From Efficiency Data - If efficiency data is entered as optional data in the Compressor curve, this option can be selected and the thermal effects of the compressor due to compression heating will be calculated. The efficiency data will be applied as isentropic efficiency, which is defined as the ideal work for an isentropic process over the actual work.

Check Valve at Discharge (No Backflow Allowed)

If this option is checked when modeling a centrifugal compressor with a compressor curve, a check valve that can be considered part of the compressor itself is assumed to exist. This will never allow backflow at the compressor junction. If a check valve closes as part of the steady-state simulation, Arrow will perform recalculations under the assumption that the compressor's check valve is closed. Note that a steady check valve position must be attained in order for Arrow to apply its steady-state calculations.

-

Forward Velocity to Close - The flow velocity, in the forward direction, that causes the check valve to close, preventing any further flow. A negative value in this field indicates that a reverse flow below the specified value will be permitted through the compressor before it closes.

-

Delta Head to Re-Open - The differential head or pressure (upstream minus downstream) required to re-open the check valve.

Figure 1: Compressor model with a centrifugal compressor curve defined

Related Topics

Compressor/Fan Efficiency Data

Compression Ratio Reference Inlet Conditions

Positive Displacement Compressor

Related Examples

Related Blogs