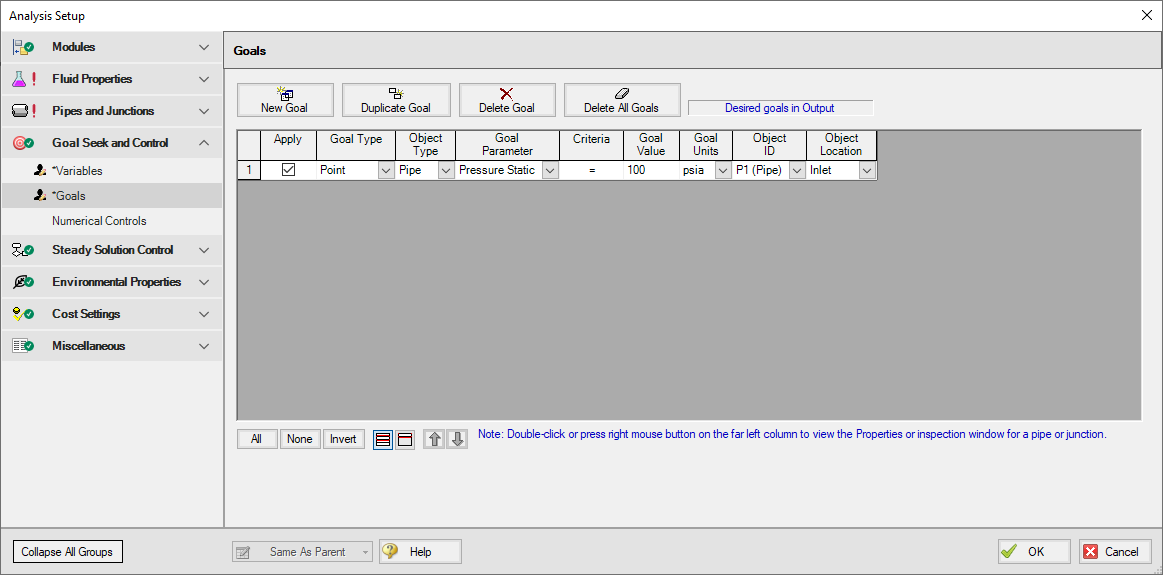

Goals Panel

(GSC Module Only) The Goals panel is where goals are defined and applied for use with the GSC module (Figure 1). Goals are output values you would like to achieve. The GSC module adjusts the applied variables until the applied goals are met. Generally there should be one goal applied for each applied variable.

Figure 1: GSC Goals are output parameters to be achieved by changing the variables

Types of Goals

The GSC module offers over 150 goals applied to pipes, junctions or groups of pipes and/or junctions. Table 1 lists all of the types of goals.

Table 1: List of object types with available goals

| Object Type | Goals | Restrictions/Comments |

| Pipe |

Energy Gradeline Head Gradient Head Loss Heat Rate Into Pipe* Hydraulic Gradeline Mass Flow Rate Pressure Drop Friction Pressure Gradient Pressure Stagnation Pressure Static Pressure Static Maximum Pressure Static Minimum Temperature* Temperature Insulation #1 Surface* Temperature Insulation #2 Surface* Temperature Insulation #3 Surface* Temperature Loss* Temperature Outer Surface* Velocity Volumetric Flow Rate Wall Temperature* |

*Only With Heat Transfer

|

|

Area Change Bend Check Valve General Component Jet Pump Orifice Relief Valve Screen Valve Venturi Volume Balance |

Energy Gradeline Hydraulic Gradeline Mass Flow Rate Pressure Stagnation Pressure Static Temperature* Volumetric Flow Rate |

*Only With Heat Transfer

|

|

Branch

|

Energy Gradeline Hydraulic Gradeline Mass Flow Rate* Pressure Stagnation Pressure Static Temperature** Volumetric Flow Rate* |

*Net Flow Rate **Only With Heat Transfer |

| Assigned Flow |

Energy Gradeline Hydraulic Gradeline Pressure Stagnation Pressure Static |

|

|

Assigned Pressure Reservoir |

Mass Flow Rate Net into Jct* Vol. Flow Rate Net into Jct* |

*Net Flow Rate |

| Control Valve |

Cv* Energy Gradeline** Hydraulic Gradeline** Kv* Mass Flow Rate*** Open Percentage* Pressure Loss^ Pressure Stagnation** Pressure Static** Temperature^^ Volumetric Flow Rate*** |

*If Open Percent Data Exists **Only for FCV ***Only for PRV, PSV ^Not PDCV ^^Only with Heat Transfer |

|

Dead End |

Pressure Hydraulic Gradeline |

|

| Heat Exchanger |

Energy Gradeline Heat Rate In* Hydraulic Gradeline Mass Flow Rate Pressure Stagnation Pressure Static Temperature** Volumetric Flow Rate |

*Only with Heat Transfer. For non-fixed heat rate exchanger models.

**Only with Heat Transfer. For non-controlled temperature models.

|

| Pump |

% of BEP Energy Gradeline Head Rise* Hydraulic Gradeline Mass Flow Rate** NPSH Margin Absolute NPSH Ratio Power Overall Pressure Rise* Pressure Stagnation Pressure Static Temperature*** Volumetric Flow Rate** |

*Only for non-fixed head rise pumps

**Only for non-fixed flow pumps

***Only with Heat Transfer

|

| Spray Discharge |

Mass Flow Rate Out* Volumetric Flow Rate Out* |

*Net Flow Rate |

|

Tee or Wye Three Way Valve |

Energy Gradeline Hydraulic Gradeline Pressure Stagnation Pressure Static Temperature* |

*Only With Heat Transfer |

Creating and Deleting Goals

To create a goal, click the New Goal button on the Goals tab. This will insert a new item into the goals list. After the goal has been added, the goal data is defined by entering the necessary data in each of the data columns.

Goals may also be added by duplicating an existing goal, then modifying the data for the new goal. To duplicate a goal, select the goal to be duplicated from the goal list, and click the Duplicate Goal button.

To delete a goal, select the goal by clicking on the appropriate row in the goal list. After selecting the goal to be deleted, click the Delete Goal button. If you want to delete all of the goals in the list, click the Delete All Goals button.

Defining Goals

For each goal the following settings can be defined:

-

Goal Type - Select the type of goal to be used from the following:

-

Point Goal - A point goal is specified when the desired goal can be specified at a specific object location in the model.

-

Differential Goal - A differential goal is used when the goal value is actually determined by the difference in values between two specific object locations. An example of a differential goal might be the pressure difference between two locations in the model.

-

Group Goal - A Group goal is used when a goal is to be applied to a group of objects at the same time. In order to use a Group goal, all of the objects must be added to a Group by using the Groups command on the Edit menu.

-

-

Object Type - Select the type of object to which the goal is to be applied. See the section below for further description of the object types.

-

Goal Parameter - Select the type of goal to be applied to the selected object, such as pressure, flow rate, or temperature.

-

Criteria - Specify the criteria which is to be met for the specified goal parameter, such as equals, greater than or equal, or less than or equal.

-

Goal Value/Units - Specify the value and units for the goal parameter.

-

Object ID - Specify the pipe, junction, or group name to which the goal applies.

-

Object Location - Specify, as appropriate, whether the goal applies to the inlet or outlet of the selected object or group.

Organizing Content

The lower left corner of the panel features options for rearranging and selecting variables and goals. All will select all available variable or goals. None will deselect all variables or goals. Invert will invert which variables and goals are selected. There are also options to show all variables or goals and to show only the applied variables or goals. The goals and variables can also be reordered using the turquoise arrows to change their position.

The Same As Parent button allows the variables, goals, numerical control, or all of the parameters (in regards to the Goal Seek and Control group) of the parent scenario to be copied down to the child scenario.

Object Types

For Point and Differential goal types, the object type indicates whether the goal is to be applied to a pipe or a junction object. If the goal is to be applied to a junction, the type of junction is selected from the list.

For the Group goal type, the user must select between a Group Max/Min or a Group Sum object type.

A Group Max/Min goal allows a single goal to be applied to a group of objects. The GSC module applies a Group Max/Min goal by ensuring the final goal value is either greater than or equal to (a Min goal) or less then or equal to (a Max goal) the specified value for each object in the group. For example, a Group Max/Min goal can be applied to ensure a minimum flow rate out of each spray discharge nozzle in a group of nozzles. Group Max/Min goals only work for groups where all group members are of the same type (i.e., all pipes or all valve junctions).

A Group Sum goal is used to set the sum of the goal parameter for all the members in a group to a specified value. For example, the Group Sum goal can be applied to set the sum of the volumetric flow rates through all of the nozzles in a group of spray discharge nozzles to a particular value. Groups used in Group Sum goals can consist of pipes and/or junctions, with junctions of different type.

Applying Goals

Once a goal has been created, the user must specify if a goal is to be used when GSC is run. To apply a goal, select the checkbox in the Apply column.

Using the Apply feature allows the user to define multiple goals that can be used in alternate cases or analyses. Any of the goals that are not being used for a particular analysis can remain in the list for later use. Click the Apply checkbox for the goals that are to be used in the current analysis.

Reviewing Pipe/Junction Data

Data for the selected objects in the Goals panel can be reviewed and edited without having to close the Analysis Setup window.

-

Reviewing object input data - If you would like to see the input data for the junction selected as a goal, press the right mouse button on the far left column in the Goals table. The inspection window will display, showing you the input data. This feature does not work for group goals.

-

Editing object input data - Similar to the inspection feature just described, you can open the Pipe or Junction Properties Window by double-clicking the far left column in the Goals table. From there you can change any data desired. This feature does not work for group goals.