Dependent Design Cases Panel

Dependent Designs are a powerful way of accounting for different operating cases during the sizing process. This panel displays information on how to create a Dependent Design Case, or if one exists, how the objects are related to their base objects.

Enabling Dependent Design Cases

Dependent Design Cases are enabled by checking the box on the Sizing Objective panel.

Figure 1: The Enable Dependent Design Cases option selected

Note: Once a Dependent Design Case exists, this option cannot be turned off unless the Dependent Design Case is completely removed.

Creating a Dependent Design Case

Once the option above has been enabled, it is possible to create Dependent Design Cases on the Workspace.

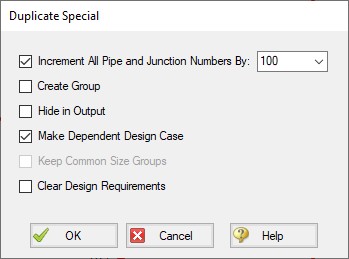

This is done simply with Duplicate Special. Select all of the objects to be included in the Dependent Design and select Duplicate Special from the Edit menu, and selecting the special Make Dependent Design Case option.

Figure 2: The Duplicate Special window can be used to create Dependent Design Cases

Selecting OK will duplicate all of the objects selected and increment their numbers by the indicated value. In addition, the new objects will be related to their base objects.

Modifying the Dependent Design

Dependent Design objects represent the same object that they were created from. Logically, the end result must be that the objects are the same in all dependent designs. It does not make logical sense for pipes to be different lengths, for example. ANS will force a single pipe diameters across all dependent designs.

However, there are many modifications that are reasonable, and they fall into two categories:

-

Modifying the physical configuration of the model - Environmental changes can affect temperature, changing processes can change the fluid, tank liquid levels can change, pumps may be brought online, valves may change position, and even new pipes may be added to represent a planned expansion. These are just a few examples of a different operating case being the result of a physically changed model.

-

Modifying the Design Requirements - The exact same physical system may still have different requirements under different conditions. A plant may have different demands during day or night, or it may be desired to account for future production without modifying the piping layout. These are a couple of examples of changing Design Requirements to create different operating cases.

Note: The only sizing input that can be changed for a Dependent Design are the Design Requirements. Remember that both the base object and Dependent Design object really represent just one physical object - it cannot have different cost or be of a different pipe material in different cases.

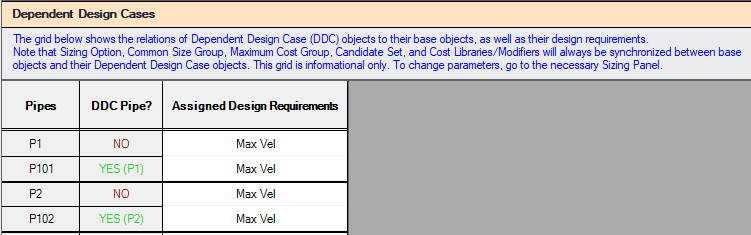

Reviewing Dependent Designs

As the model becomes larger and more complex, it may be difficult to tell what objects correspond to others across operating cases. The Dependent Design Cases panel (Figure 2) shows a review of how the objects are connected:

Figure 3: The Dependent Design Cases panel