Size/Cost Assignments Panel

The Size/Cost Assignments panel defines which components are to be included or excluded from sizing and cost reporting. Buttons across the top of the panel display selections for a specific component type.

Pipes

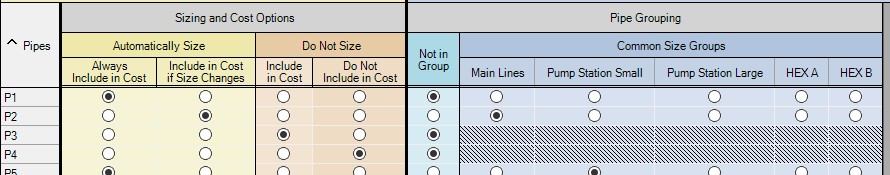

The options for pipes include including or excluding them from sizing, including or excluding from cost, including in cost only if size changes, and collecting the pipes into Common Size Groups (Figure 1).

-

Sizing and Cost Options - This section of the table controls sizing and cost calculation.

-

Automatically Size - If either of these columns are selected, this pipe will be included in the sizing analysis.

-

Always Include in Cost - The cost of this pipe will always be considered and reported.

-

Include in Cost if Size Changes - The cost of this pipe will effectively be considered zero for the initial size. This is useful for representing existing pipes, while considering the cost savings that could result from replacing the existing pipe with one of a more appropriate size.

-

-

Do Not Size - If either of these columns are selected, this pipe will not be included in the sizing analysis.

-

Include in Cost - The pipe will not be considered for sizing, but the cost of the pipe for the user specified size will be included. This is useful for having a complete picture of the system cost, even if certain pipes must be a given size.

-

Do Not Include in Cost - The pipe will not be sized or included in costs.

-

-

-

Pipe Grouping - Pipes can be placed into Common Size Groups here. You can sort this table by clicking on the column headers, or by right-clicking on the headers and choosing Organize Grid by Common Size Group.

-

Not in Group - the pipe is not in a group, and is either not sized, or sized independently from any other pipe.

-

Common Size Groups - This section is only visible after a Common Size Group is created with the New button. When a Common Size Group is created, it will create a corresponding column underneath the Common Size Groups header. Pipes can then be placed into the Common Size Group by selecting the radio button for the given pipe under the given Common Size Group. Groups can be collected to the top of the table by clicking on their column headers.

-

Figure 1: The options for including pipes in both sizing and cost calculation. Additionally, the options to create custom size groups is shown.

Note: You can also add Pipes to Common Size Groups directly from the Workspace, and optionally color the Workspace pipes to indicate which pipes are in what groups.

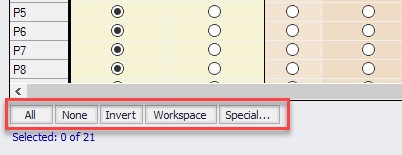

Pipes can be selected by clicking on the row header, and multiple pipes can be selected by holding control or shift. With multiple pipes selected, their sizing or cost options can be reassigned with the buttons near the top of the table. All of the tables displayed in this panel include the selection features(Figure 2) available elsewhere in AFT Fathom.

Figure 2: Selection options available for the Size/Cost Assignments panel

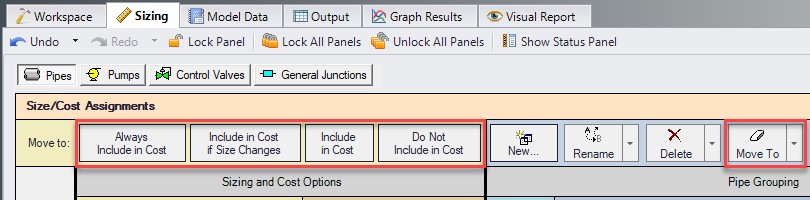

Selected rows can have their settings changed all at once with the buttons just above the table (Figure 3).

Figure 3: The buttons above the table can be used to change selected rows all at once

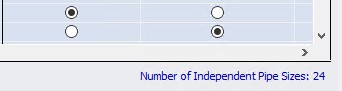

Note the indication of the total number of Independent Pipe Sizes in the lower right (Figure 4). This quantity has important implications on run time and what Search Method will be appropriate for the model.

Figure 4: The Number of Independent Pipe Sizes in the model are shown which has implications on runtime

Pumps, Control Valves, and Junctions

-

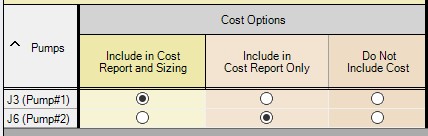

Cost Options - This section of the table controls sizing and cost calculation (Figure 5).

-

Include in Cost Report and Sizing - If a junction is included in the sizing calculation, this does not mean that the junction itself is modified as pipes are. Instead, this means that the cost associated with the junction is included in the Objective. This can indirectly affect the size of the junction as the pipes are sized accordingly around it.

-

Include in Cost Report Only - The junction cost will not be included in the Objective. However, the cost of the junction will be included in the Cost Report. The sizing of the junction may change as a result of pipe size changes, but the cost impact of this change will not drive the solution.

-

Do Not Include Cost - Not included in sizing or costs.

-

Figure 5: Cost options available for Pumps, Control Valves, and Junctions

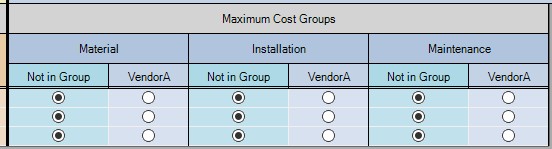

Maximum Cost Groups

Pumps and Control valves can optionally be grouped together in maximum cost groups (Figure 6). This is useful to account for situations where the cost of multiple components is the same, regardless of how the system operates around them.

For example, it is common to have two identical pumps installed in parallel, with only one operating and the other functioning as a spare. Clearly, the cost of purchasing and installing two identical pumps will be identical regardless of how they end up being operated. The automated sizing calculation will base the cost of the pump off its required size to maintain the desired flow. However, in the case of a spare there is no flow requested, meaning that the ideal size of pump is "zero" - no pump at all! ANS must be told that the spare pump is the same size as the running pump. This will force the costs to be the same, accounting for both in the sizing.

In any Maximum Cost Group, the largest cost found during sizing will be applied to all of the junctions in the group for the given category. There are three categories:

-

Material - The most common grouping - A set of identical junctions will likely cost the same to procure, and therefore should be placed into a Material Maximum Cost Group.

-

Installation - Commonly tied to Material - the junctions are likely to cost the same to install.

-

Maintenance - May or may not be grouped - if all junctions have routine maintenance whether or not they are used, they should be grouped. If maintenance occurs only when the junction is operating for some amount of time, then a spare will have different maintenance costs and they should not be grouped.

Figure 6: The Maximum Cost Groups feature is shown allowing for items with identical costs to be grouped together

Related Blogs

What is the ANS Module Asking For? Introduction to the Sizing window in the ANS Add-on Module